Anyone looking for moisture analyzers ultimately wants one thing above all: fast, reliable moisture values that stand up to audits and really help in the process, whether in incoming goods inspection, in the laboratory or directly on the production line.

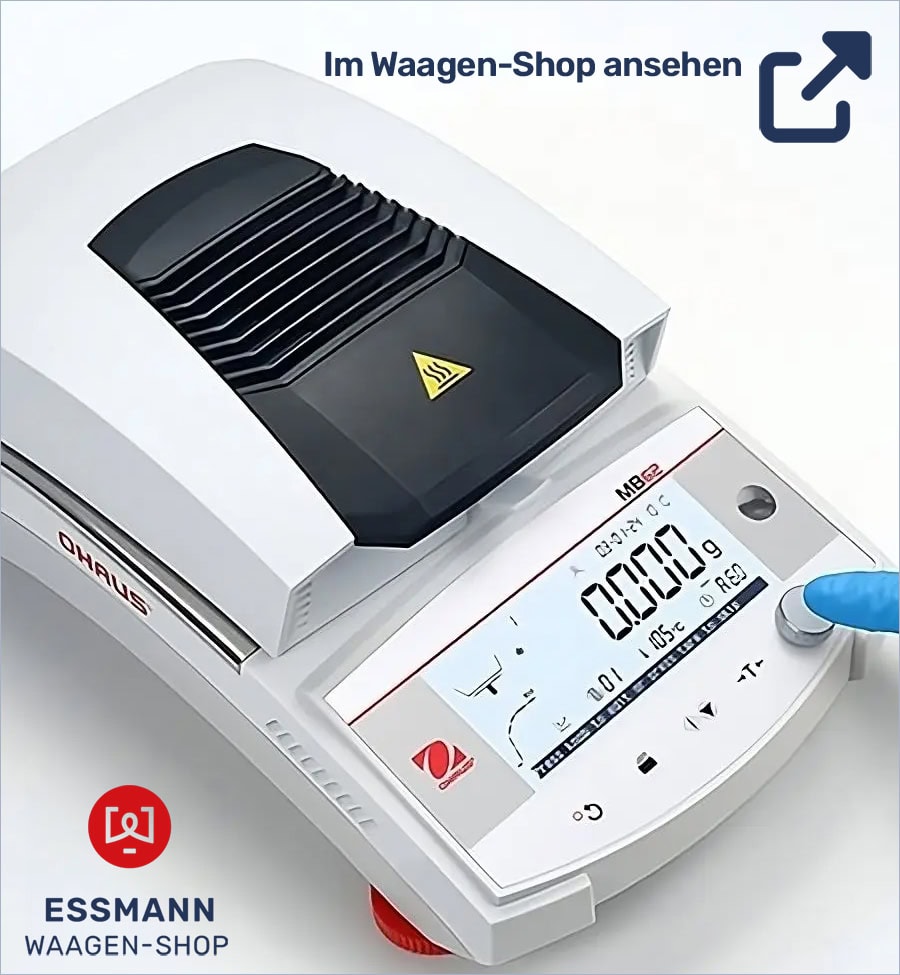

The OHAUS MB series (MB32, MB62, MB92) relies on a modern concept of carbon fibre IR heating, improved load cell and robust design. The result: short drying times, reproducible measurements and intuitive operation.

What is a moisture analyzer and what is it used for?

A moisture analyzer determines the moisture content of a sample using the thermogravimetric measuring method: the sample is weighed, then heated and the scale continuously tracks the decrease in weight. The device uses this difference to calculate % moisture or % dry matter, among other things.

Typical areas of application and why humidity is crucial there:

- Food (flour, spices, baked goods, snacks): Stability, shelf life, declaration, reject rate

- Pharmaceuticals & chemicals (powders, granulates): Recipe consistency, process reliability, batch documentation

- Plastics & polymers: processability, bubble formation, mechanical properties

- Paper, pulp, building materials: process control, drying costs, end product quality

What makes the OHAUS MB series technically special

1. carbon fiber IR heating technology: fast, uniform, close to the process

OHAUS uses a carbon fiber IR heater (carbon fiber infrared) for the MB32/MB62/MB92. This design is designed to dry samples quickly and evenly – a real advantage when throughput and reproducibility count.

2. modernized load cell: basis for stable results

In thermogravimetric measurement, the load cell plays a decisive role in how well a device cleanly resolves small changes in weight. OHAUS calls the MB series an upgraded load cell.

3. 90 g maximum load, 1 mg / 0.01 % readability

For many laboratory and QA samples, the practical world ranges from “a few grams” to “more substance for inhomogeneous samples”. The MB models are typically designed for 90 g (across all models) and offer 1 mg / 0.01 % readability for the moisture value – suitable for routine and many demanding applications.

MB32, MB62 or MB92? Selection according to everyday life instead of data sheet

The question “Which model is right?” is best answered from within the company: How often do you measure? How critical are methodology, documentation and data security?

OHAUS MB32: The robust routine moisture analyzer

The MB32 is the entry into the new MB generation – designed for routine moisture testing in laboratories and production. OHAUS emphasizes the new housing design, the carbon-heating technology and the improved load cell.

Who is the MB32 particularly suitable for?

- Incoming goods & QA with clear standard samples

- Moisture checks during production (shift operation)

- Laboratories that want simple, stable, reproducible measurements

Practical benefits that you notice in everyday life:

- Short measuring times thanks to carbon heating

- Operating logic that works even after weeks without training

- Robust design for harsh environments (e.g. flour dust, sugar, spices)

OHAUS MB62: More methodological flexibility for changing samples

The MB62 is designed for more flexible applications: Method creation, settings and access to data are thought of more broadly than with the routine device. Also here: new housing, carbon IR heating, improved load cell.(us.ohaus.com)

Typical reasons for MB62 instead of MB32:

- You have several product groups (e.g. powders + pastes + granulates)

- You want to customize drying profiles / switch-off criteria

- You need reproducible methods in the team (shift / location)

OHAUS MB92: When data security, ease of use and audit routines count

The MB92 is the “workhorse” for more demanding environments – with a capacitive full-color touchscreen and additional data integrity / data security functions (e.g. password protection). OHAUS also emphasizes the ease of cleaning through design elements such as glass front and tool-free heating chamber assembly (depending on version/option).

When the MB92 makes sense in practice:

- You work in regulated environments (e.g. pharma-related QA) or with strict customer requirements

- You need secure user roles/passwords and comprehensible operating procedures

- You want to switch quickly between methods and document measurement series cleanly

Typical errors in moisture analysis – and how to avoid them

A moisture analyzer is quick to use – but measurement reliability stands and falls with methodology and handling.

Solution: Introduce a cleaning routine (tray, heating chamber, sealing surfaces), especially for sticky samples

Sample not representative (too coarse, too inhomogeneous, wrong sample quantity)

Solution: Homogenize sample, select suitable sample mass, crush if necessary

Incorrect drying profile (too hot → decomposition; too cold → endless)

Solution: Adapt the profile/temperature to the material, select a sensible switch-off criterion

Temperature not checked/calibrated

Solution: Perform temperature adjustment/check regularly – this is a key point for consistent results.

Cleaning is forgotten

Solution: Introduce a cleaning routine (tray, heating chamber, sealing surfaces), especially for sticky samples

Mini checklist: How to find the right OHAUS moisture analyzer

If you want to reach a reliable decision quickly, this list will help:

- Sample types: powder, granulate, paste, liquid, hygroscopic?

- Frequency: 5 measurements/day or 50 per shift?

- Documentation: Is a printout/export sufficient – or do you need roles/passwords?

- Cleaning: Dusty/sticky/corrosive? (plan cleaning effort realistically)

- Location: Laboratory or production (vibrations, draughts, temperature changes)

In short::

MB92 = Touch + higher requirements for data integrity and ease of use

MB32 = routine, robust, economical

MB62 = more method flexibility and parametrics

FAQ: Frequently asked questions about OHAUS moisture analyzers

How accurate is an OHAUS moisture analyzer?

The MB models are typically specified with 1 mg / 0.01 % readability for moisture values. In practice, the quality of the results depends heavily on the sample, methodology and temperature control.

What does “thermogravimetric” mean?

The moisture content is determined indirectly by measuring the weight loss during heating and calculating the moisture content from this.

Carbon heater vs. halogen – is it better?

“Better” depends on the goal. The OHAUS MB series relies on carbon fiber heating, which is designed for fast, even drying. The decisive factors remain: suitable profile, correct switch-off criterion, clean temperature control.

What is the ideal sample size?

As much as necessary for representativeness, as little as possible for fast, uniform drying. Several grams are often useful for inhomogeneous materials – test the repeatability with your sample.

Conclusion: OHAUS MB series as a practical solution for routine to audit environments

The OHAUS MB moisture analyzers (MB32, MB62, MB92) are consistently designed for throughput, stable results and suitability for everyday use – with carbon IR heating, improved load cell and a different focus on methodology and data security depending on the model.

If you properly “measure” 2-3 of your typical samples before purchasing them, this will save you the most time later on: tighten the method, check the switch-off criterion, document repeatability – then the moisture analyzer becomes a reliable QA tool instead of a topic of discussion.

Do you have any questions?

If you want to use OHAUS moisture analyzers (MB32/MB62/MB92) in the laboratory or production, it is worth carrying out a brief practical check in advance: Which sample, which profile, which documentation requirement?

In the ESSMANN scales store we support you in selecting the right device – and ensure reliable results in everyday life with our Germany-wide service (commissioning, maintenance, calibration/testing concepts as required).