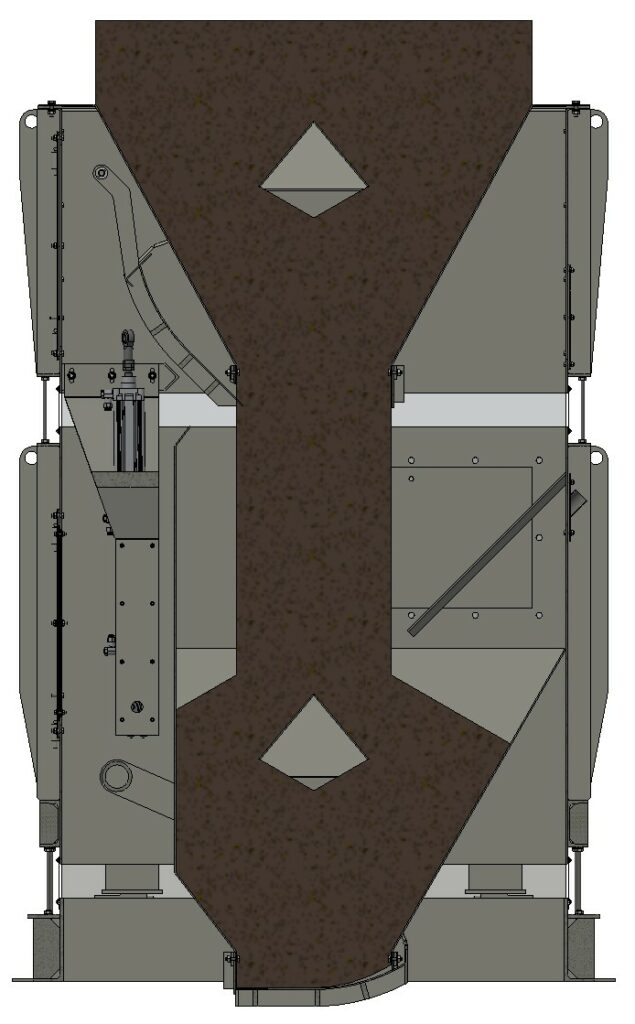

Functionality of a continuous scale, bulk material scale or hopper scale HE-BW

A hopper scale usually consists of a pre- and post-hopper and a weighing hopper. The weighing hopper is filled with a bulk material using a conveyor system (e.g. screw conveyor or belt conveyor). The pre-hopper is open.

Once a specified target weight or time has been reached, the pre-hopper is closed. The weighing hopper is now weighed exactly, during which time the pre-hopper continues to be filled.

The weighing result is stored and evaluated in our high-performance weighing terminal EWS. This enables the exact weighing of batches, e.g. when loading and unloading trucks, trains or ships. The special flap geometry enables the weighing hopper to be emptied quickly afterwards.

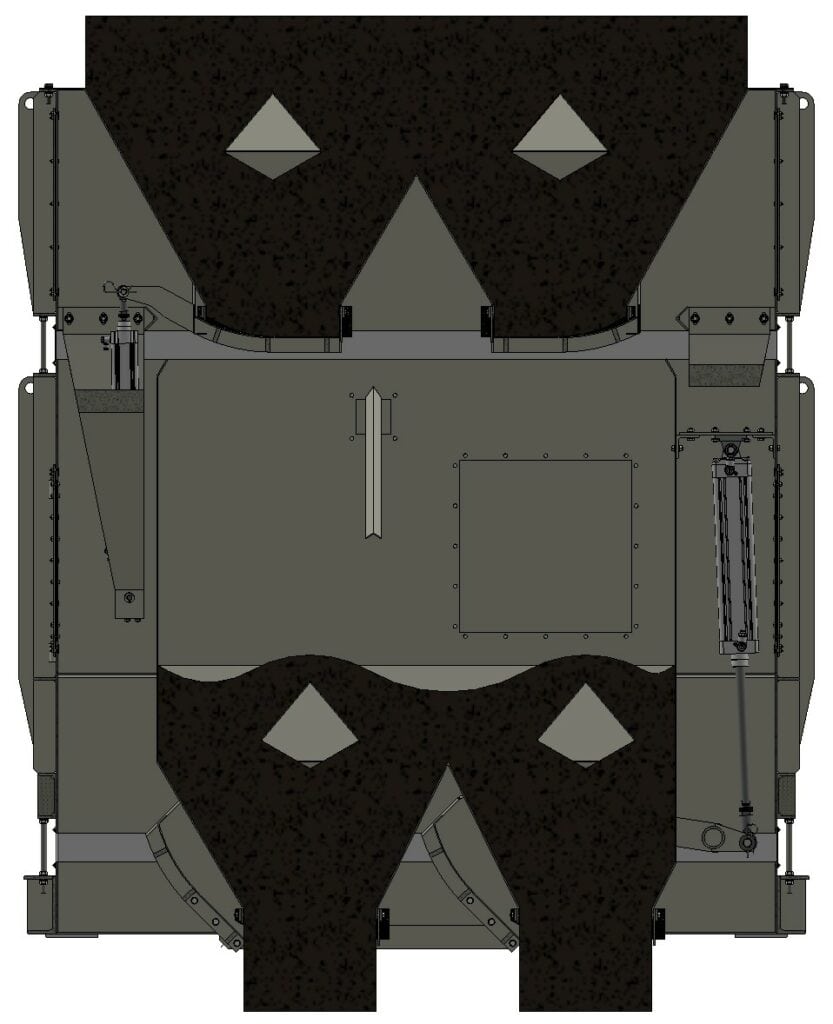

Filling and weighing on a continuous scale with one flap

The weighing hopper can then be filled by opening the pre-hopper again and the cycle is repeated.

The HE-Bulk software software is also suitable for monitoring and controlling process sequences, as various parameters can be output and forwarded to higher-level control systems.

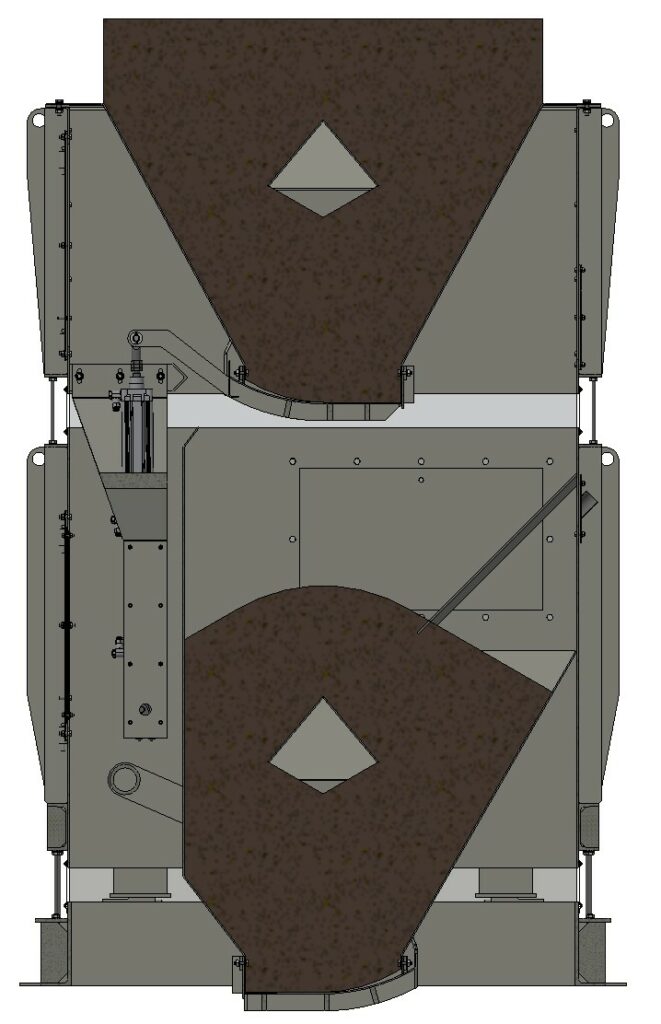

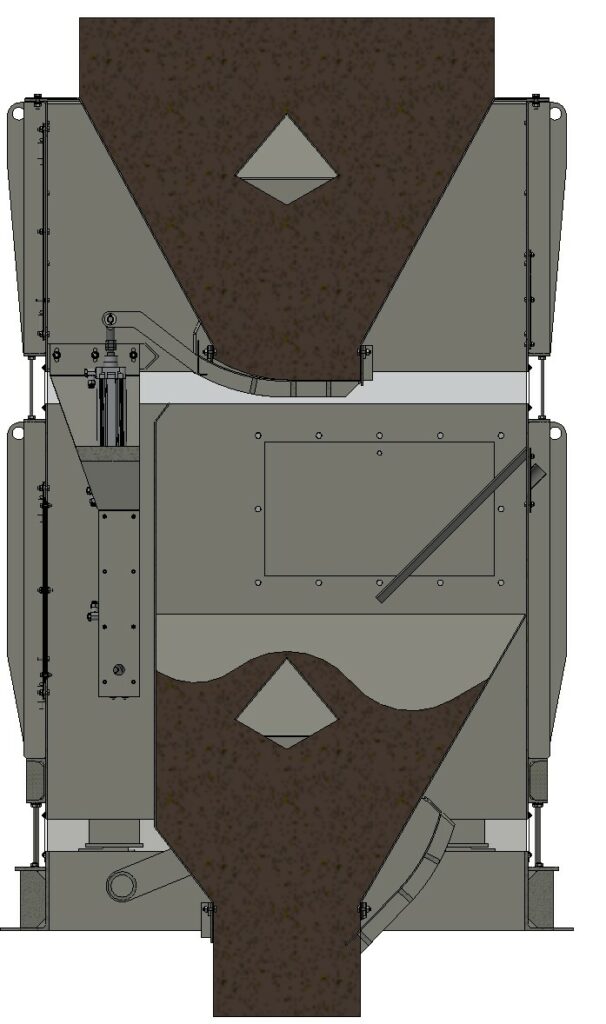

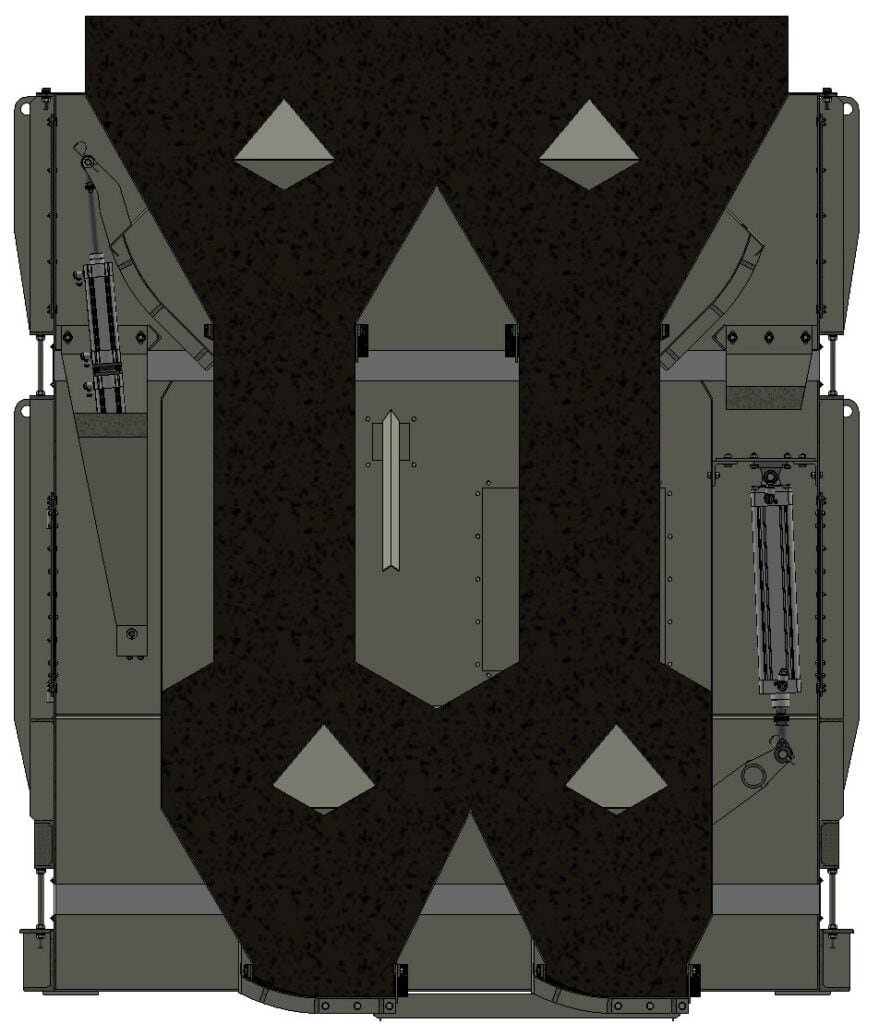

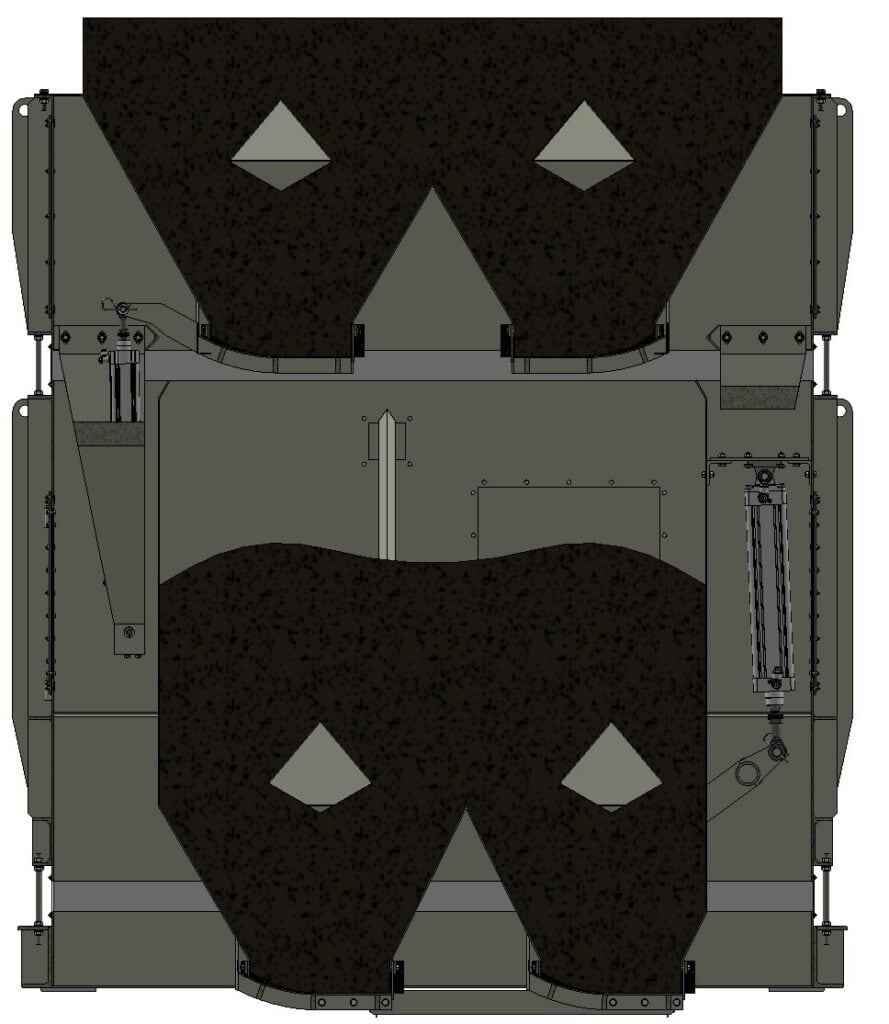

Double or even triple flap openings are used for larger flow rates.

Filling and weighing with continuous scales with two flaps

Functionality of a tank scale and silo scale

In industry, liquids, powders, solids and gases are stored and processed in various vessels, tanks and containers. A common and cost-effective method of weighing silos and tanks is the use of weigh modules. Essmann offers high-quality stainless steel weigh modules that are ideal for weighing tanks and silos in the food and pharmaceutical industries.

The Essmann weighing modules for tank scales and silo scales offer a standardized, compact and cost-effective solution for a wide range of nominal loads, from 100 kg up to 50 t. To ensure precise weight measurement, Essmann compression load cells made of stainless steel are used. These are equipped with adapter plates at the top and bottom, lift-off protection as well as lateral force and torque-free force application.

Thanks to the Essmann weighing modules, large tanks and containers can be weighed continuously and the fill level can be determined based on the weight. This enables stable operating processes and reliable monitoring of fill levels.

Scale builder tip: Customizability

ESSMANN | Waagen & Automation offers a wide range of state-of-the-art scales and automation solutions. Our continuous scales, hopper scales, transfer scales, receiving and loading scales, dosing systems and bagging scales are sophisticated down to the smallest detail and ensure smooth operations. Thanks to our high degree of flexibility, we can offer customized systems for every application. Our handling scales are characterized by freedom from maintenance and high measuring accuracy. This is guaranteed by the use of wear-resistant and rustproof built-in parts in conjunction with precision stainless steel load cells with a high degree of protection.

“Our two continuous scales in two bulk material silos are running perfectly, and our software customization requests have all been implemented.”

– Christian Blaffert, former Wismar seaport