ESSMANN | Waagen & Automation has developed an extra-long mobile truck scale for a long-standing customer in the building materials industry. HE-TS mobile truck scale with a length of 30 m with a weighing house and load control and successfully put it into operation.

Customer

The company is an experienced manufacturer of industrial gypsum products with over 160 years of know-how. Since its foundation and the establishment of extraction and production facilities, the company has continuously developed its technical skills in gypsum production and successfully led it into the future.

Requirements for the long truck scales

The Bundesverband der Gipsindustrie e.V. has published a leaflet describing the safe handling of construction site silos. A customer needed a new loading system consisting of two large silos. In order to load the trucks evenly and still only use one truck scale, the scale had to be long enough to allow a truck to park under both silos. ESSMANN | Waagen & Automation developed a 30 meter long truck scale based on the mobile and modular HE-TS truck scale. Due to the extraordinary length of the scale, the modern steel construction of the HE-TS truck scale from ESSMANN | Waagen & Automation was the ideal solution.

Technical solution

ESSMANN | Waagen & Automation advised the customer intensively and together they developed a technical solution consisting of the 30 meter long mobile truck scale HE-TS and a driver self-service terminal in a weighing house. The HE-Archiv9000 weighing software developed by ESSMANN | Waagen & Automation is used for convenient and fast maintenance of master data and weighing records.

Implementation

Installation and commissioning of the long truck scales

The installation of the long truck scale with load control on a driver self-service terminal is carried out by our service technicians. For this purpose, the customer will carry out any necessary leveling of the paved, concrete or asphalt surface according to our specifications if this

is uneven and has height differences. A special foundation is not required for the mobile truck scales. In addition, the customer provides a forklift truck or similar with driver for unloading and mounting the scales.

The driver self-service system has already been commissioned at the ESSMANN | Waagen & Automation factory. Here, technicians planned, drew and manufactured the system. At the same time, the software programmers from ESSMANN | Waagen & Automation implemented the customer’s special requirements in both the loading control system and the weighing program. The entire system was then set up and tested in the factory and then shipped to the construction site.

Thanks to this extensive preparation and strict quality control by ESSMANN | Waagen & Automation, the service technicians on site were able to quickly commission the entire system and carry out operator training.

Calibration of the long truck scales

The truck scales from ESSMANN | Waagen & Automation are of course legal for trade. The extra-long truck scales are no exception, despite being custom-made. However, calibration played a central role in the project planning and design phase right from the start. The challenging accessibility of the truck scales due to the silo foundations and pillars and the fact that the connection area had not yet been completed at the time of calibration made calibration a complex task. For this reason, ESSMANN | Waagen & Automation carried out a simulation of the calibration right at the beginning in order to ensure the technical feasibility of the entire project before submitting the offer and placing the order.

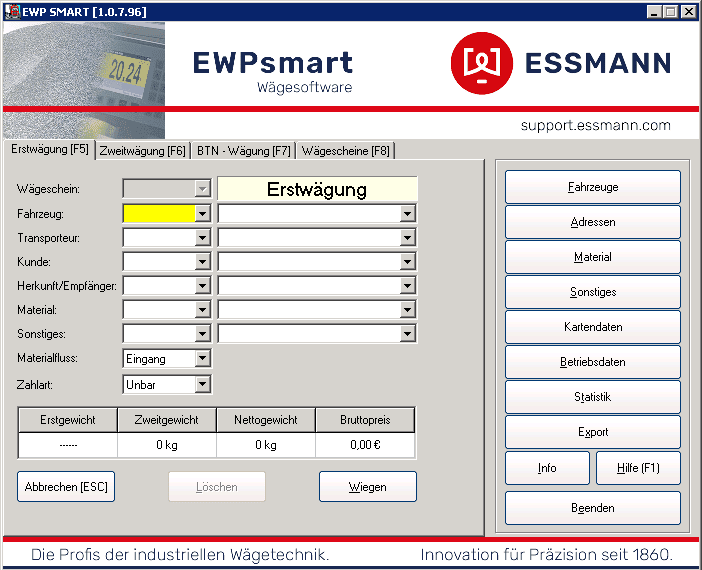

All master data is stored on the EWS-8000E weighing electronics in the driver self-service terminal in the weighing house. The master data can be maintained directly on the weighing electronics via an externally connectable keyboard or via an EWP PC workstation workstation.

The HE-Archiv9000 weighing software was developed by ESSMANN | Waagen & Automation to conveniently maintain master data on weighing electronics and read out weighing data.