EWA Cargo Control – Digital cargo control directly on the vehicle

EWA Cargo Control is a mobile extension of the ➚ESSMANN weighing software EWP for seamless documentation and inspection of vehicle loads in the incoming and outgoing process. The application runs on a robust industrial tablet and supports employees at recycling centers, waste-to-energy plants and similar facilities in legally compliant and efficient material control.

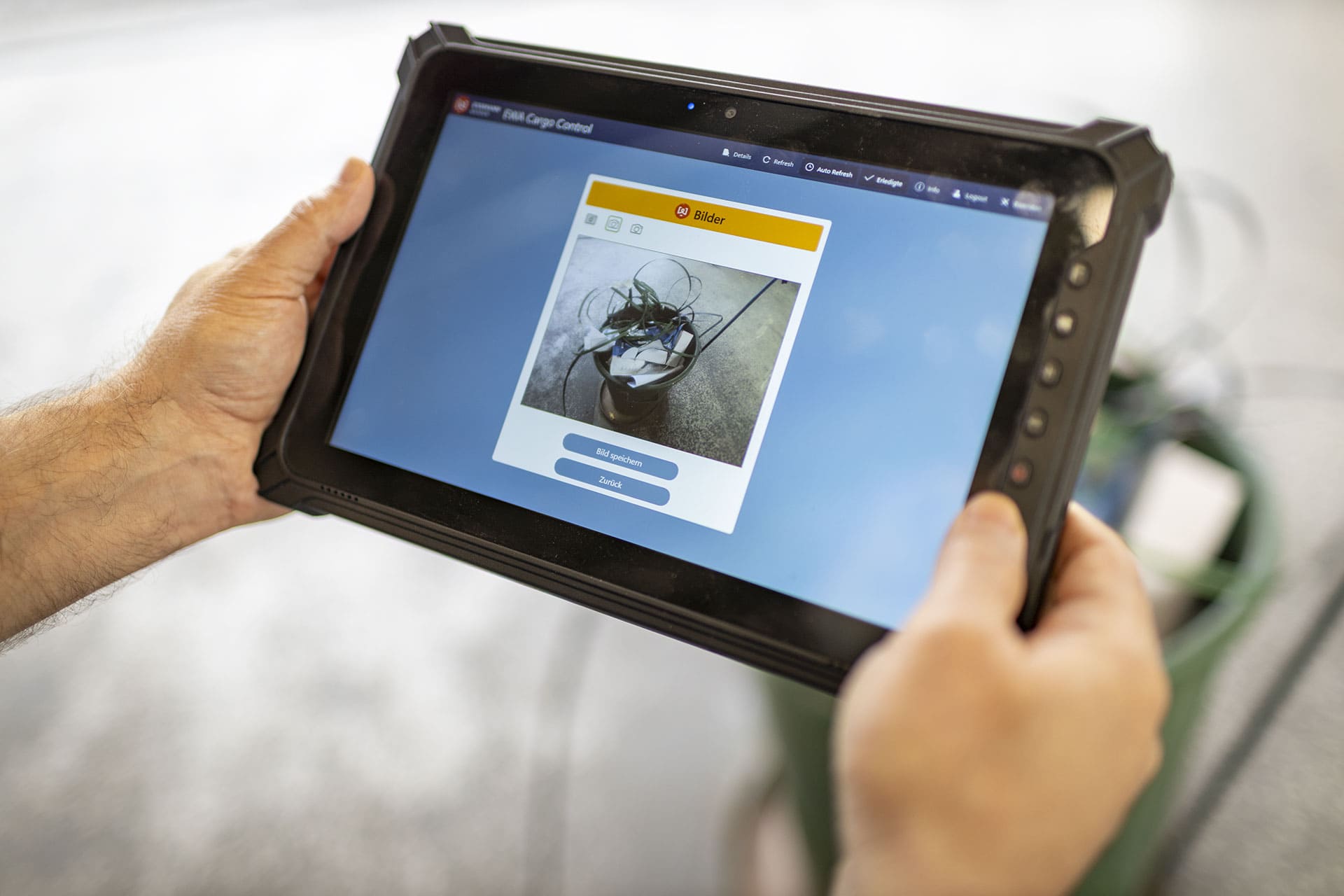

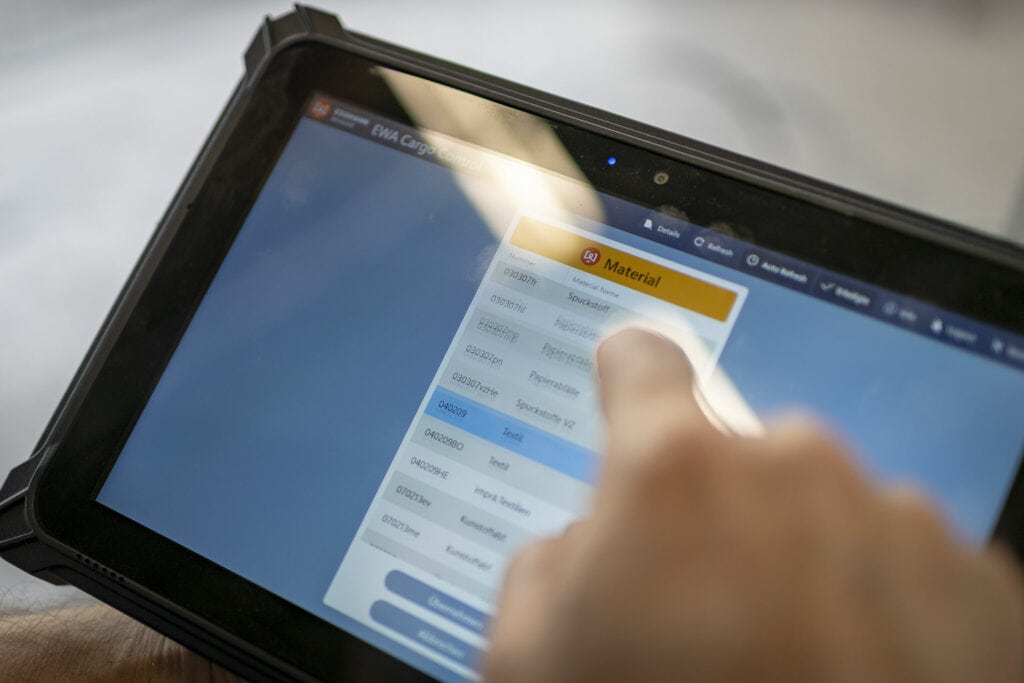

The process is completely digital and free of media discontinuity: After the incoming weighing, the vehicle drives to the unloading point. There, the specialist staff check the load, record the materials it contains, mark impurities or spillage and can document the condition of the freight photographically. This data is immediately transmitted to the EWP software and appears in the yard list – visible to the weighing personnel. The process is also identical for vehicles arriving empty that are loaded on the premises: the check is carried out before the outgoing weighing and all information is automatically entered into the central data record.

Especially in the waste disposal and recycling industry, EWA Cargo Control solves a number of typical problems: paper-based loading reports or loose notes are a thing of the past – receipts can no longer get lost. The automatic linking of control and weighing data prevents incorrect allocations and erroneous invoicing. At the same time, the software meets waste legislation requirements for visual inspections, for example for hazardous or declarable substances. End-to-end digital processes eliminate media disruptions and increase data quality – a decisive advantage for companies that value audit compliance, transparency and efficiency.

Its use also brings measurable economic benefits: Reduced personnel costs, faster process cycles and fewer complaints thanks to precise, traceable material recording. For internal quality management, EWA Cargo Control provides a powerful tool for documenting material flows, detecting faulty items at an early stage and increasing operational reliability.

Technical functionality at a glance

The application integrates seamlessly into existing weighing systems with EWP backend:

- Live synchronization with the yard list: Controlled vehicles are marked in real time.

- Photo documentation directly via the tablet camera.

- Material selection from predefined list, optionally with impurity and spit material labeling.

- Independent use with loaded and unloaded vehicles, before or after weighing.

- Automatic comparison with weighing data on exit.

The software not only supplements weight recording, but also documents the material composition of the freight – a critical factor for quality assurance, billing models and official requirements.

Prerequisites for use

- EWP weighing software with activated yard list function.

- Industrial tablet with camera, WLAN or LTE.

- Network connection to the EWP instance, local or cloud-based.

- Access rights for control personnel, via user administration in EWP.

Full integration into the EWA process does not require any adaptation of the truck scales themselves – it is purely a software extension on the yard logistics side.

Application benefits in practice

- Legal certainty: fulfillment of obligations in the case of visual inspections prescribed by waste legislation.

- Quality control: Detection and documentation of incorrect or undeclared materials.

- Process reliability: avoidance of incorrect loading when vehicles arrive empty.

- Verification: Traceability in the event of complaints or limit value violations.

Would you like to integrate EWA Cargo Control into your yard logistics?

Our experts will be happy to advise you on technical requirements, integration and piloting: