Powerful functions for your

yard management

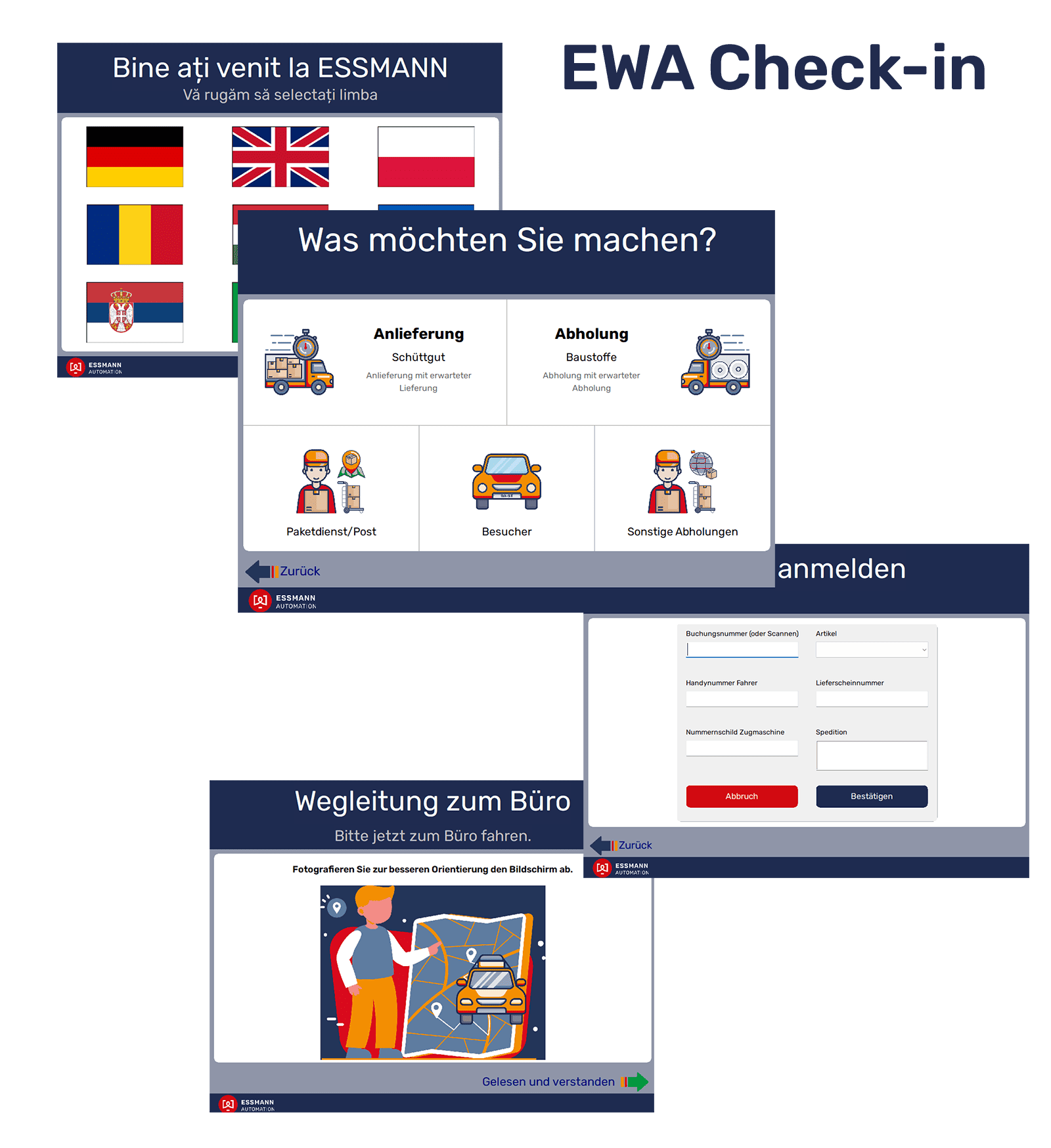

- Flexible registration: Multilingual driver self-service via app, handheld transmitter or weighing personnel

- Safety checks & instructions for drivers and suppliers

- Automated capture & control: scanner, license plate recognition, digital signatures

- Seamless integration: connection to scales, loading and unloading automation

- Seamless documentation: electronic records for the transportation & disposal of hazardous waste

- ERP and logistics interfaces: Data exchange with ERP, merchandise management and transport management systems

- Automated vehicle detection: barrier, gate and traffic light control

- Real-time control & monitoring: live overview of logged-in vehicles & suppliers

- Timeslot management: connection to systems such as Transporeon or Couplink

- Individual customization: Configurable time and loading management solutions

- Comprehensive reports & data interfaces for performance analysis

Optimized control of your operating processes ensures efficiency and safety on the farm

Yard management or yard control refers to the control of all processes in a company’s depot – from the entry and exit of trucks and their weighing, to navigation on the site using intelligent vehicle guidance solutions, to the coordination of loading and unloading processes at the ramps. For a long time, this area was considered a marginal discipline alongside warehouse management (WMS) and transport management (TMS), but digitized yard logistics offers advantages that are becoming the focus of more and more companies.

The advantages of a sophisticated yard management system are obvious:

- Reduced personnel and time expenditure

- Higher throughput capacity

- Shorter waiting times and demurrage charges

- Fewer manual errors, less correction effort

- Better planning capability

- Lower risk thanks to organized processes

- Improved utilization of warehouse and gates

- Safety in compliance with legal metrological requirements

All of these factors combined lead to an attractive ROI. Many companies achieve a return on their YMS investment within just one year.

Tried and tested solutions from ESSMANN for your plant logistics

The ESSMANN Yard Management System is a proven, continuously developed solution for the safe, efficient and error-free control of goods movements, weighing and material flows on your premises. It ensures optimized processes and transparent workflows for companies of all sizes.

Automation & digitalization for smooth processes

Our system offers innovative functions such as driver self-service, automated log-on and log-off as well as mobile solutions such as the EWA remote app for control and documentation. This automation reduces errors, relieves your staff and increases efficiency.

Why the ESSMANN Yard Management System?

The ESSMANN Yard Management System offers pre-configured controls for traffic lights,

barriers, position detection, gates and more.

Integration with transport management platforms and logistics solutions makes ESSMANN Yard Management the perfect interface between carriers, customers and suppliers.

In combination with our EWP scales software, the system enables seamless process mapping from the scales to invoicing and cash management.

Your advantages at a glance:

- Fast implementation: preconfigured modules make deployment easier

- High integration capability: open interfaces for ERP, TMS and WMS systems

- Maximum security: proven in KRITIS environments, flexible as a local or web-based solution

- Sustainability & quality: High-quality stainless steel or RAL-painted components, software & hardware from a single source

- Flexible usage concepts: purchase, rental or leasing for individual requirements

ESSMANN Yard Management FAQ

How can the ESSMANN Yard Management System be integrated into an existing software landscape??

Our open interfaces allow the yard control system to be securely and stably integrated into existing systems. The modular structure allows the solution to grow with your requirements.

How secure is the ESSMANN Yard Management System?

The demonstrably successful use, particularly by customers with critical infrastructure (KRITIS), demonstrates the particular robustness of the system. Depending on the configuration, the systems can be operated completely independently or integrated into web-based solutions.

How sustainable are ESSMANN’s yard management systems?

We supply the columns, cabinets and appliances in stainless steel or painted in RAL colors according to your requirements. All production and software development is carried out in-house at ESSMANN, so you only need one contact person. Our flexible offers from purchase to rental provide you with maximum bandwidth according to your requirements.

In addition, we offer transparent software care & maintenance packages for your future-proof application from ESSMANN.

How does the ESSMANN Yard Management System support error-free and efficient processes?

Only registered goods transports are allowed to enter your yard or facility in accordance with your specifications and planning. Automated vehicle detection, position monitoring and barriers safeguard your processes and prevent errors and time-consuming corrections.

The seamless documentation fulfills all reporting requirements and creates transparency between partners. Digital signatures and safety instructions on the log-on terminal support your safety and oblige your partners to treat each other fairly. The support of mobile devices for the drivers of your wheel loaders, carriers and your inspection personnel, for example, makes work safe, simple and traceable. Documented final inspections, confirmations and checkouts ensure transparency and avoid errors and bottlenecks in processes.

ESSMANN Yard Management

Your path to optimal yard management

We accompany you step by step in the development of your optimal yard management solution – from the initial consultation through to successful implementation. Our proven process ensures that your individual requirements are optimally met:

1. initial consultation & requirements analysis

We will clarify your specific requirements and challenges in an initial meeting. You will receive an initial assessment of possible solutions and optimization potential.

2. on-site inspection & process analysis

Our experts visit your plant, analyze your current processes and identify potential for improvement. This enables us to ensure that our solution is perfectly tailored to your circumstances.

3. concept development with tried-and-tested reference solutions

Based on the findings from the analysis, we develop a customized concept. We draw on tried-and-tested reference solutions to integrate tried-and-tested methods and technologies into your system.

4. presentation & individual customization

We present you with the developed concept and make adjustments to further adapt the solution to your requirements.

5. Optional visit to a reference system

To give you an impression of how our solutions work in practice, we can organize a tour of an existing reference system at one of our customers’ premises on request.

6. offer preparation & decision

You receive a transparent and detailed offer with a clear cost and time plan.

7. implementation & commissioning

Once you have made your decision, we support you during implementation – from installation and integration into existing systems to training your employees and a maintenance concept.

This structured process ensures that your ESSMANN Yard Management System fits your requirements perfectly and enables maximum efficiency and safety in your plant logistics.

Rely on future-proof, flexible yard management that adapts to your needs!