HE Wägetechnik’s trolley bridges, draw-wire and suspension crane scales with electro-mechanical weighing technology are calibratable weighing devices (accuracy class III, commercially calibratable) that can be fitted to almost all crane systems.

As the weighing devices to be installed are part of the crane, the installation should be carefully checked at the planning stage.

Retrofitting a weighing device to a crane is only possible to a limited extent.

Intended use:

The calibratable weighing of bulk and general cargo in the grab or on the hook during handling by crane or loading bridge.

The weighing device is particularly required for handling goods from ship to barge or storage yard or wagon.

Working principle:

The crane operator can operate the weighing device during crane operation.

The loads can be weighed at any height of the grab or hook tackle.

The grab contents or the load on the hook are displayed digitally to the crane operator and printed on a measurement printer.

Intermediate and final totals can be printed out and displayed as required.

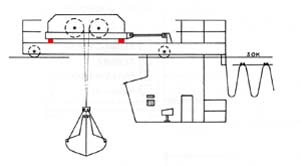

Trolley bridge scales

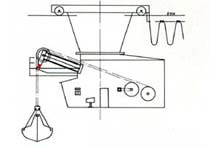

HE Wägetechnik trolley bridge scales are calibratable and are mainly used in loading bridges for bulk goods handling. The characteristic of the trolley bridge scales is that all masses of the hoisting gear and the ropes are included in the weighing device as tare loads. Due to the design of the trolley, which determines this type of scale, it is not necessary to balance the ropes, as is the case with rope pull scales.

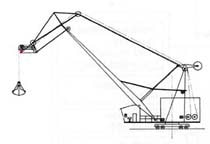

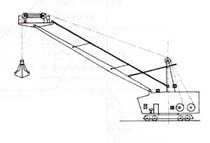

Schematic diagram of the trolley bridge scale

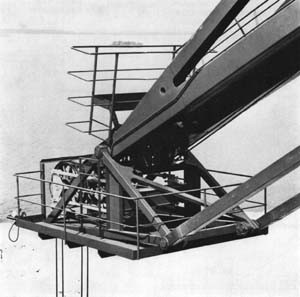

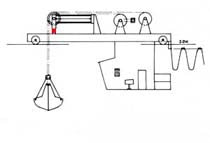

Draw-wire scales

The tension occurring on the crane ropes corresponds to the weight of the load plus the weight of the freely suspended ropes and can be determined from the driver’s cab with calibratable accuracy. The crane operator can initiate the weighing process and check the results while operating the crane. The vertical pull – required to determine the weight – is transmitted to the weighing device via strain gauge force transducers, which are marked “red” in the following schematic diagrams. The forces from the horizontal cable pull are transferred to a fixed structural part of the crane by links arranged parallel to the cable section. An automatic taring device, driven by one of the rope drums, balances the weight of the freely suspended ropes. This means that the loads can be weighed at any height. The dead weight of the grab, bucket or hook tackle is balanced on the weighing device, so the net weight of the load can always be read off or printed. Draw-wire scales from HE Wägetechnik are gentle on cables and largely maintenance-free.

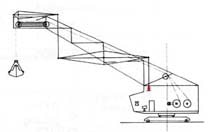

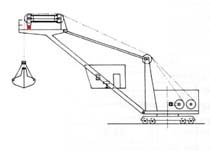

Schematic representation of different types of draw-wire scales

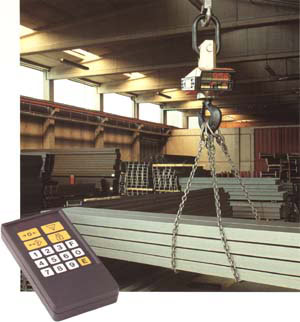

Suspension crane scales

The calibratable hook-on crane scale is a modern mobile weighing system that is hung on the hook of the trolley or crane.

The scale is very compact, robust and easy to operate via an infrared remote control.

The weight is determined by a load cell with very high accuracy and reliability.

Power is supplied by rechargeable batteries and the weight is displayed on a bright LED display.

The scale complies with the applicable safety standards and has a CE mark in accordance with Directive 90/384/EEC.

It is particularly suitable for use in general cargo handling, e.g. in steelworks, foundries, metal shops.

Optionally, the weight transmission can be transmitted via radio to a stationary receiver, e.g. for connection to a higher-level computer (HOST).

A heat shield and a mounting device for anchor or double hooks are also available as accessories.