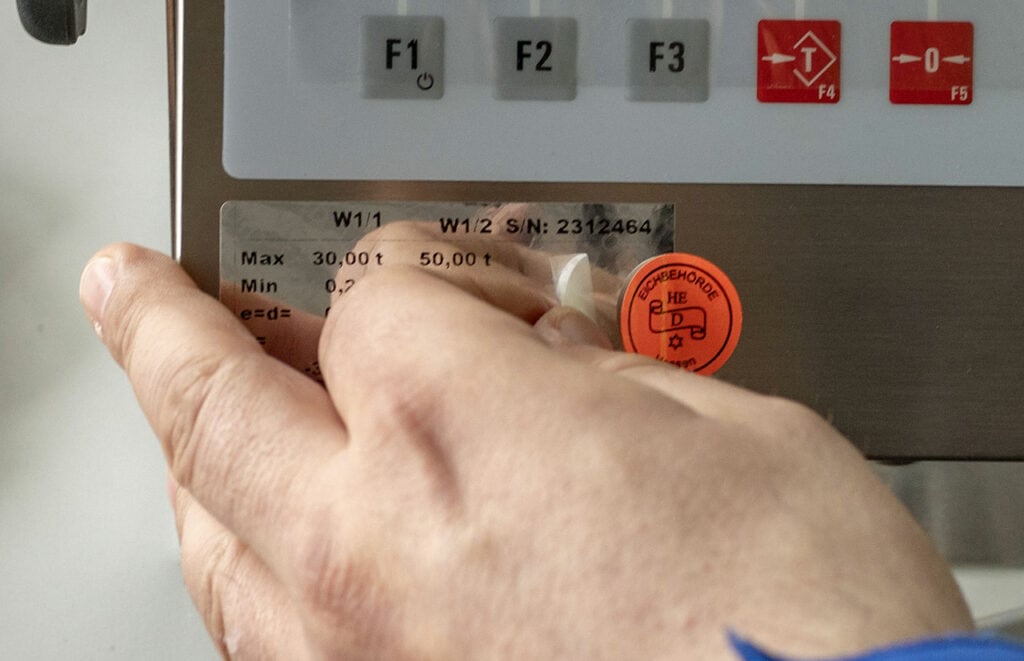

Industrial scales calibrated for precision

How often do scales have to be calibrated?

Industrial scales such as truck scales, rail scales, platform scales or bulk scales generally have to be calibrated every two years, or annually depending on the type of use. The exact calibration periods are regulated by law and are decisive for the validity of your measurement results in business transactions. ESSMANN supports you with full-service calibration management: from initial calibration to regular recalibrations and recalibrations through to DAkkS-compliant calibrations – including deadline monitoring and on-site preparation.

Rely on certified specialists and decades of experience. This not only ensures legal compliance, but also efficiency and precision in your processes.

Manufacturer calibration

Scales that are planned, delivered and commissioned via ESSMANN can be handed over ready for calibration directly ex works or on site – without additional test points, without loss of time

ESSMANN is authorized to independently carry out the complete conformity assessment procedure (manufacturer verification) in accordance with Directive 2014/31/EU for non-automatic weighing instruments (NAWIs). This is based on our certified quality management system, which fulfills the requirements of the European Measuring Instruments Directive (MID).

Recalibration

No more calibration at the last minute: we relieve you of the burden of monitoring the calibration period. We keep a structured digital device file with all technical parameters, service events and the next calibration due date for every scale we manage.

Our system automatically reminds you at the right time – and we take care of the entire organization of the upcoming calibration, including coordination with the inspection body and preparation service.

DAkkS calibration with normative safety

ESSMANN | Waagen & Automation offers DAkkS-compliant calibrations via the accredited calibration laboratory of KERN & SOHN GmbH. Whether laboratory, industrial or process scales: our technical interface ensures traceable measurement results in accordance with DIN EN ISO/IEC 17025 – documented, recognized and auditable.

Ideal for companies with QM systems according to ISO 9001, GMP or GLP.

Information about important appointment reminder! Smooth processing. Absolutely friendly and appreciative communication.”

– Katja Stoppel