Our best weighing terminals in comparison

Good weighing terminals can do more than just determine the weight. They log the values in a verifiable manner and link them to master data, can be networked with the EWP weighing software and can be used for a wide range of scales, from laboratory scales to dynamic rail scales. With the help of our experienced technical team from ESSMANN | Waagen & Automation, we have tested three weighing terminals ranging from €579.00 to €2,254.00 net for measuring accuracy, features and ease of use and can tell you which models we can recommend for which application.

Weighing terminals put to the test: three smart models put to the test

Wer etwas wiegen will, möchte in den seltensten Fällen einfach nur das Gewicht anzeigen. Das Ziel besteht vielmehr darin die Waage in meist schon bestehende Prozesse smart einzubinden oder einen neuen Wägeprozess gleich digital abzubilden. Sogenannte Wägeterminals, auch Wägeindikator oder Wägeelektronik genannt, helfen dabei: Sie bestimmen das Gewicht der angeschlossenen Waage (beispielsweise einer Plattformwaage oder LKW Waage), steuern aktiv Wägeprozesse (von einer Umschlagwaage oder dynamischen Gleiswaage) und lassen sich mit der darauf abgestimmten Wägesoftware EWP so in das digitale Netzwerk einbinden, dass der Nutzer den Wägeprozess einfach steuern und die erzeugten Wägedaten direkt im ERP System ablegen kann.

It’s a good thing that weighing terminals are now not much more expensive than conventional industrial PCs. We have compared three models that determine the weight, control different types of scales and display this weighing data clearly in the EWP weighing software. We found out how well this really works with the help of our technical team from ESSMANN | Waagen & Automation, whose years of experience with the devices have been incorporated. We present our top recommendations in the table below.

Would you like to know more? Following our top recommendations from the test field, we explain exactly how weighing terminals work and what you should look out for in order to select the right weighing terminal.

Comparison: Overview of the 3 best weighing terminals

| Properties | Our recommendation | Price-performance winner | Best equipment |

|---|---|---|---|

| Designation | EWS-3 | EWS-1 | EWS-8000E |

| Overall grade | 1.2 (very good) | 1.8 (good) | 1.4 (very good) |

| Calibratability | for use as a non-automatic weighing instrument | for use as a non-automatic weighing instrument | for use as non-automatic and automatic scales |

| Integrated application software | 7 programs | 4 programs | 13+ programs (optionally available and individually programmable) |

| Typical areas of application | Truck scales, counting scales, checkweighers, simple filling controllers, in the PC network, for weighing and dosing in the fieldbus, in hazardous areas | Floor and bench scales, checkweighers, hopper scales, mobile scales | Filling and dosing systems, receiving/loading scales, belt scales, checkweighers, sample checkweighers, truck scales, wheel load scales, mobile scales, shipping scales, counting scales and piece counting dosing systems |

| Display size | 5″ color screen for weight display, operator dialogs and calibration | 4.3″ color screen for weight display, operator dialogs and calibration | 5.7″ color screen with wide viewing angle and large weight display, operator dialogs and calibration |

| Interfaces | 2 internal scale connections, can be integrated into PC networks via Ethernet or WLAN, connection to label printer and network printer, PLC connection via fieldbus | 1 internal scale connection, can be integrated into PC networks via Ethernet, connection to label printers and network printers | 2 internal and up to 6 external scale connections, can be integrated into PC networks via Ethernet or WLAN, connection to label printers and network printers, PLC connection via fieldbus |

| ESSMANN Prize | from € 923.00 net incl. scale connection | from € 579.00 net incl. scale discount | from € 2,254.00 net incl. scale connection |

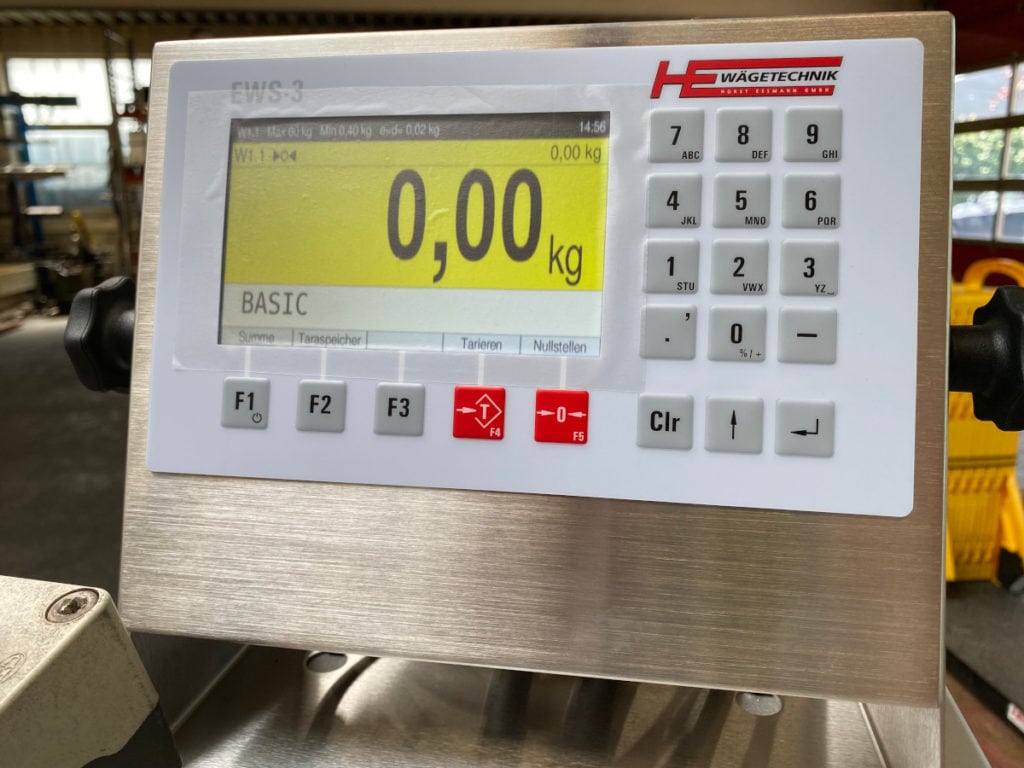

The best weighing terminal in the long-term test: EWS-3

Good from experience:

The EWS-3 weighing terminal from ESSMANN | Waagen & Automation is used most frequently by our team

| Strengths | Weaknesses |

|---|---|

| Verifiable for use as a non-automatic weighing instrument | Default application software The weighing terminal EWS-3 cannot be individually programmed. |

| High ease of use intuitive multilingual user guidance, bright 5″ color screen for weight display, user dialogs and calibration | Limited number of interfaces The interfaces (RS232, RS485, RJ45 Ethernet, Profinet/Profibus, input/output modules) are only available in limited quantities and may restrict the application. |

| Robust Stainless steel housing (EWS-3: IP69K; EWS-3 Ex: IP65), cable feeds via sealed cable glands, suitable for harsh environmental conditions and high hygiene requirements, e.g. in chemical, pharmaceutical and food processing plants | Limited verifiability Verifiable only for use as a non-automatic weighing instrument |

| Can be integrated into PC networks or fieldbus systems | |

| Variable Available as a wall/table version and for switch cabinet mounting | |

| ATEX The EWS-3 Ex2/22 device variant is ideal for potentially explosive atmospheres |

Summary of the weighing terminal EWS-3

The EWS-3 weighing terminal came out on top in the test field thanks to its ease of use and versatile features. Particularly noteworthy are the well thought-out details, such as the robust stainless steel housing in IP69K and the keypad, which also withstands the high hygiene requirements in industries such as food, pharmaceuticals and chemicals. The weighing terminal is easy to configure and offers pre-installed application programs for various applications. The clear design and easy-to-read display, which can be customized, are further plus points.

The weighing terminal can be connected to analog strain gauge scales and can be used as a multi-range or multi-interval scale. Digital load cells can also be connected as an option. The weighing programs display net, tare or gross weight and allow the input of up to 20 additional data such as order, customer or material numbers via user-friendly operator guidance. Optionally, the weighing data can also be stored on the weighing terminal. It is also possible to record quantities or totalize weights. The EWS-3 can be expanded with additional modules. Fully configurable weighing receipts can be printed on labels or forms using an optional printer. The data can be transferred to the PC and saved after each weighing. An optional interface allows the weighing terminal to be operated from a PC to retrieve, tare and zero the weight. The weight can also be stored on the PC for legal-for-trade purposes when using EWP and other additional software tools. The weighing terminal can also be used for switching and batching via optional input/output modules, where two weight limits can be monitored. Weighing and taring can also be started via external buttons. Alternatively, the inputs/outputs can be used for simple filling processes with start and stop buttons.

The price-performance winner for standard use: EWS-1 weighing terminal

Inexpensive and precise: The EWS-1 weighing terminal from ESSMANN | Weighing & Automation for simple tasks.

| Strengths | Weaknesses |

|---|---|

| Verifiable for use as a non-automatic weighing instrument | Default application software The weighing terminal EWS-1 has only a few programs and cannot be individually programmed. |

| Cost-effective with a very good price/performance ratio for simple tasks. | Very limited number of interfaces The interfaces (RS232, RS485, RJ45 Ethernet, input/output modules) are only available in very limited numbers and can restrict the application. |

| Easy to use Simple multilingual user guidance, bright 4.3″ color screen for weight display, user dialogs and calibration | Verifiability Verifiable only for use as a non-automatic weighing instrument |

| Robust Stainless steel housing IP69K, all cable feeds via sealed cable glands, suitable for harsh environmental conditions and high hygiene requirements, e.g. in chemical, pharmaceutical and food processing plants | |

| Can be integrated into PC networks. | |

| Variable Available as a wall/table version and for switch cabinet mounting |

Summary of the weighing terminal EWS-1

The EWS-1 weighing terminal is characterized by its reduced design, which facilitates operation for simple applications. It has just a few keys and offers clear user guidance. In addition to displaying the gross, net and tare weights, it can also record the weight or quantity. Optionally, the weighing information can also be stored internally on the weighing terminal EWS-1 in a verifiable form. Configurable printouts can be created on label or form printers that display the weight, weight totals, date, time and serial number. The terminal can be connected and operated via an optional PC interface. It is also possible to use the terminal for switching and dosing with monitoring of weight limit values.

The biggest difference to the test winner of the weighing terminals is that the EWS-1 only has one slot for extensions (either serial or Ethernet interface module) and does not offer a WLAN option. The available application programs are also limited. Overall, the EWS-1 is a recommendable weighing terminal for anyone who is not only interested in weight, but also in price and can cope with the standard weighing information. It offers good performance at a reasonable price.

The giant among weighing terminals: the EWS-8000E

The best-equipped weighing terminal EWS-8000E from ESSMANN | Waagen & Automation has been developed for demanding tasks.

| Strengths | Weaknesses |

|---|---|

| Calibratable for use as automatic and non-automatic scales | Maximum flexibility has its price The comprehensive weighing terminal EWS-8000E is the most expensive device in the comparison. |

| High ease of use Simple multilingual user guidance, bright 5″ color screen with alphanumeric keypad for weight display, user dialogs and calibration | |

| Robust Stainless steel housing (EWS-8000E: IP69K; EWS-8000E Ex2/22 and EWS-8000ET: IP65), all cable feeds via sealed cable glands, suitable for harsh environmental conditions and high hygiene requirements, e.g. in chemical, pharmaceutical and food processing plants | |

| Universally applicable Numerous standard application programs for a wide range of weighing applications and free programmability for customer-specific adaptations. | |

| Variable Available as a wall/table version and for switch cabinet mounting | |

Summary of the EWS-8000E weighing terminal

The EWS-8000E weighing terminal offers numerous functions and interfaces. It enables the selection of different application programs and can also be customized if required. This enables solutions for different areas:

- Incoming goods and shipping

- Filling and dosing systems

- Receiving/loading scales

- Checkweighers

- Truck scales, truck scales, wheel load weighing systems

- Mobile data acquisition / weighing system

- Driver self-service systems

The weighing terminal’s display is large and well-lit, making it easy to read even in difficult lighting conditions or with visual impairments. This makes the weighing terminal impressive in terms of features.

However, setting up the weighing terminal is quite complex. Although it can be quickly connected to the scale, adjusting the weighing terminal requires specialist knowledge and takes a lot of time. We therefore recommend having the set-up carried out by ESSMANN | Waagen & Automation. If required, additional application options can be implemented by our development team.

On the positive side, the scales are WLAN-capable and can be quickly integrated into PC networks thanks to the Linux-based operating system with integrated web server functionality.

Purchasing advice for weighing terminals: These are the things you should consider when choosing a weighing terminal

1. scale connection

The most important feature of all our weighing terminals in the test is the scale connection. Depending on the application, one or more scales are connected to a weighing terminal. Analog strain gauge load cells or digital load cells from different manufacturers or digital weighing platforms and precision scales can be connected. The applications range from simple static weight recording to dynamic rail scales.

2. place of use

Depending on the application and installation location, different requirements are placed on the weighing terminal. If the weighing terminal is installed outdoors, it must at least be protected against splashing water (rain). In the food and pharmaceutical industries, the housing must be made of stainless steel and be able to withstand cleaning with a steam jet. Our EWS weighing terminals are ideally equipped with protection class IP65 and IP69K. In the chemical industry, on the other hand, resistance to certain acids and bases is also required. Our front foil with integrated membrane keypad is resistant to all common solvents and cleaning agents. When used in switchgear, there should be a high level of compatibility with electromagnetic fields; our weighing terminals can withstand field strengths of up to 50V/m due to their design. In potentially explosive areas, the weighing terminal must have ATEX approval, which we offer for zones 2 and 22, as well as for zones 1 and 21.

3. calibratability

If the weight is to be recorded on the scales for commercial transactions (trade) or to determine a fee, the scales are subject to the German Measurement and Verification Act (MessEG) and the German Measurement and Verification Ordinance (MessEV). This applies in particular to scales for determining the price by weight and for the manufacture and inspection of pre-packaged goods. In such cases, the weighing terminal used must be “legal for trade”, for which a type examination certificate corresponding to the application must be available.

4. software

Weighing terminals are not only used to record the weight value. Very often, they also fulfill other tasks, for example, weighing terminals can directly control the flaps at the infeed and outfeed of a handling scale. The terminal independently calculates the opening switching points and automatically closes the flaps again before the target quantity is reached. Logging on a printer, PC or in a file are further tasks that must be performed. When selecting the weighing terminal for the application, it is therefore important to check whether there is suitable application software for the weighing terminal that meets all requirements, or whether customer-specific adaptations are required.

5. connection options to other devices

Depending on the application, the weighing terminal must communicate with other devices and be connected to them. Examples of this are receipt and/or label printers, remote weight displays and many more. Connection to a PC or network, as well as connection to a PLC, is usually a prerequisite and minimum requirement. For this, the weighing terminal must not only have the right number of interfaces, but also support the corresponding protocols. Our EWS-8000E weighing terminal, for example, as the equipment winner of all weighing terminals in the test, can be equipped with 6 interfaces. RS232, RS422/485, Ethernet TCP/IP, USB, WiFi, Profibus DP, Profinet, EtherNet IP and Modbus TCP can be configured.

Further recommendations

Mehr erfahren

Find out more in the ESSMANN scale store

Find out more in the ESSMANN scales store