Veolia has put a state-of-the-art radioactivity portal measuring system for truck passages into operation at the Marl Chemical Park. This technology is a central element of safety and quality control for the delivery of waste and sensitive material flows. It detects invisible hazards before they reach the plant. But how does such a system work technically? And what role do the truck scales and the self-service terminal play? This article classifies the technology and shows why weighing technology is more than just a weighing point in such safety concepts.

What is a portal measuring system for radiation control?

A Radiation Portal Monitor (RPM) is an automated system for detecting ionizing radiation on vehicles, containers or load carriers. It works contact-free and checks every passing vehicle for gamma or neutron radiation without unnecessarily interrupting the material flow.

Such systems are used in particular where radioactive substances could unintentionally enter the material cycle, for example in the waste disposal, recycling or chemical industries. The aim is to identify potentially contaminated deliveries at an early stage and remove them from the process in a controlled manner.

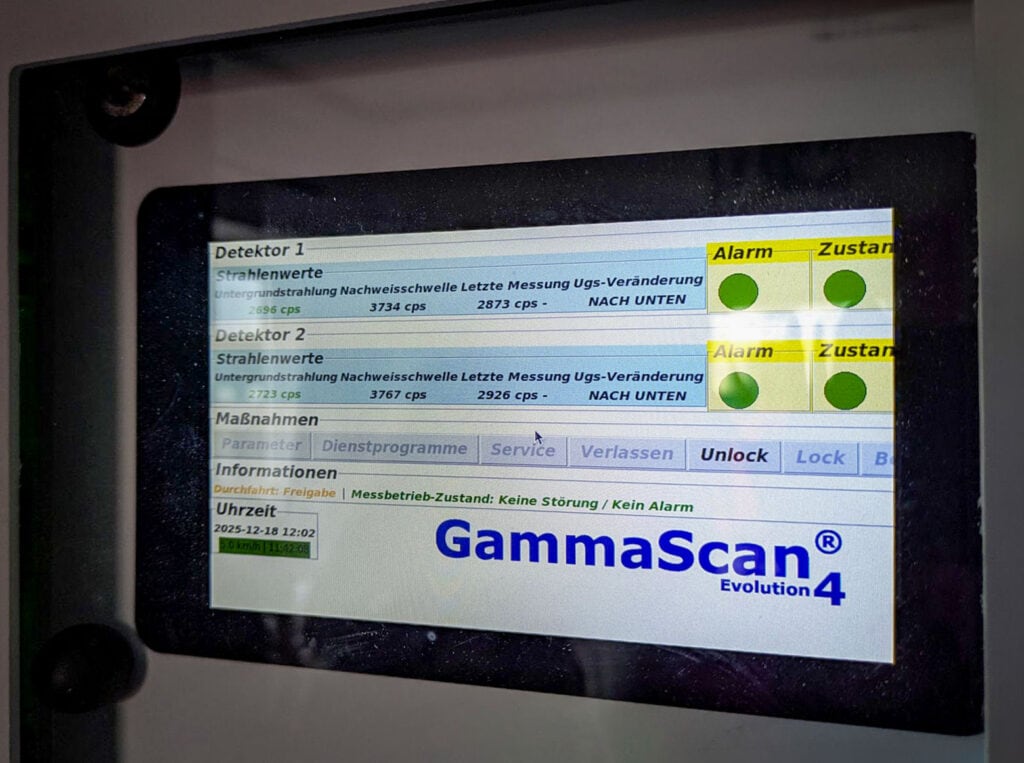

GammaScan: Everything in the green zone

Laboratory manager Dr. Anette Schünemann with Geiger counter

How does the measurement work at the Marl Chemical Park site?

The system installed at Veolia has a multi-stage structure and combines fast throughput checks with precise detailed measurement:

– Two external detectors to the left and right of the passage to the scales detect the vehicle even before the actual weighing process.

– An integrated measuring point in the area of the scales measures when the vehicle is completely within the defined measuring field.

– Mobile Geiger counters are used for subsequent measurement as soon as defined threshold values are exceeded.

Measurements are initially taken in counts per second (CPS), i.e. the number of registered decays per second. If the values are above the natural background, pre-alarm and limit values are evaluated. Only in the event of anomalies is a detailed follow-up measurement carried out using a Geiger counter in microsieverts per hour (µSv/h), which also forms the basis for a possible report to the authorities.

This two-stage process combines high operational reliability with smooth system operation.

The role of the scale: defined measuring point in the safety process

In this overall system, the truck scale is a central component, not only from a logistical but also from a metrological point of view.

The scales define the exact point at which the vehicle is fully recorded. Speed, position and standstill can be clearly checked here. This is crucial in order to obtain reproducible and comparable measurement results and to clearly assign the radiation measurement to a vehicle.

At the same time, the scales form the logical hub at which weight data and vehicle identity and safety measurements can converge: an important prerequisite for seamless documentation and subsequent traceability.

Tip for similar projects: Ideally, this process should be combined in such a way that the measurement results of the RPM are also shown directly on the weighing note. In this way, all relevant information about the vehicle and the load is documented together.

The external detectors of the radioactivity portal measuring system at the vehicle scales

Technical requirements of the chemical industry and how the HE-TS 18 fulfills them

The requirements in the chemical industry are high – especially in terms of safety, durability and precision. This is precisely where the truck scales play to their strengths.

The HE-TS 18 mobile truck scales have a torsion-resistant steel construction that remains dimensionally stable over the long term, even with high frequency and changing vehicle types. The hot-dip galvanized surface ensures maximum corrosion protection – a decisive factor for outdoor installation and aggressive environmental conditions.

The calibratable weighing electronics enable legally compliant weight recording, while the 120 mm high upstands made of galvanized angle steel on the sides ensure clear vehicle guidance. They reduce the risk of incorrect movements and protect both the scales and vehicles when driving on them.

For the operator, this means

– Reliable weight measurement in continuous operation

– Stable measurement results even in adverse weather conditions

– Safe use in a wide range of vehicle configurations

For us, it is another example of a project in which industrial precision and practical design have been consistently combined.

Security also means: professional alarm handling

One of the biggest challenges in operating such systems is not the measurement itself, but how to deal with anomalies. Every pre-alarm requires clear processes, clean documentation and – if limit values are exceeded – the involvement of the relevant authorities.

The combination of gantry measuring system, scales and terminal creates the basis for structured handling of events without unnecessarily slowing down the overall operation.

The article is based on this post on the LinkedIn presence of Veolia | Hazardous Waste Germany. Photos courtesy of Veolia.

You can also follow ESSMANN | Scales & Automation on LinkedIn.

Conclusion: When weighing technology becomes part of the safety architecture

The gantry measuring system at the Marl Chemical Park impressively demonstrates how modern sensor technology and robust weighing technology can work together.

In combination with a durable, precise truck scale such as the HE-TS 18 and an intelligent self-service terminal, the result is a system that combines safety, efficiency and documentation – and thus permanently meets the high demands of the chemical industry.

Are you planning a similar project? Contact us, we can certainly support you with our yard management solutions for all aspects of scales.

Photos: Veolia Marl