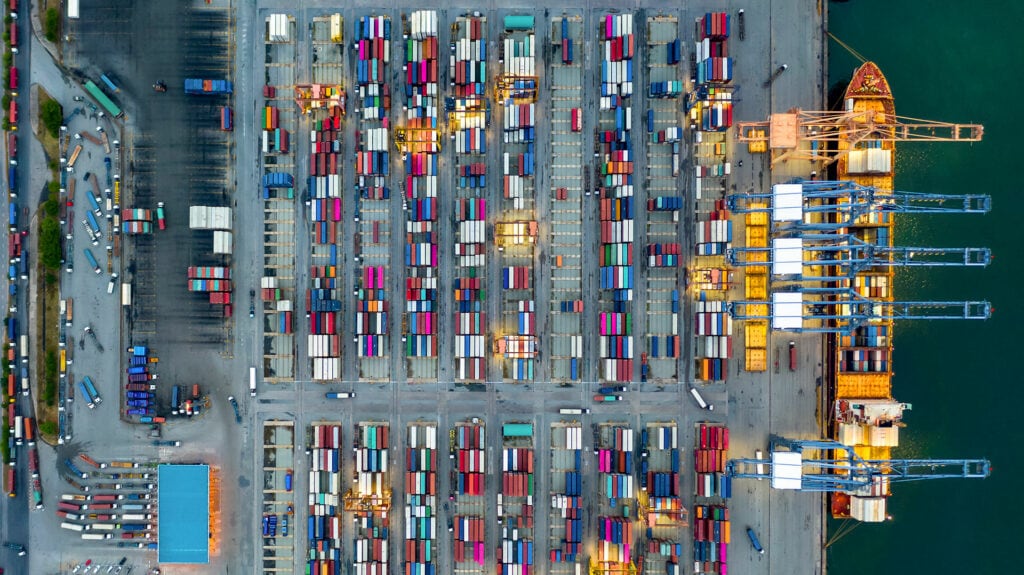

Whether it’s a container terminal or an industrial site in a port, enormous handling volumes meet high demands for speed and precision. Truck queues at the gates, strict security requirements and complex loading processes are part of everyday life. Trucks sometimes wait hours at some seaports before they are processed. In view of the 274 million tons of seaborne goods in German seaports in 2024, for example, every minute counts. The challenge for port operators: how can all vehicles – from container trucks to freight wagons – be efficiently coordinated, traceably documented and safely dispatched without losing track?

Challenges in yard management in ports

Modern port areas are complex logistics hubs. Some of the key challenges in yard management (yard logistics) in a port:

- High handling figures: Countless trucks, trailers and wagons pass through the port area every day. Peak times for ship unloading operations put entry and exit under time pressure. At peak times, there is often only a 2-hour window for the complete loading and unloading of a ship.

- Different vehicle types: Port operators have to manage road transporters, container trailers, rail wagons, forklift trucks and even special vehicles (e.g. heavy-duty modular transporters). Each type of vehicle has its own requirements for weighing technology and access control.

- Time pressure & waiting times: Long truck queues put a strain on drivers and the environment. 63% of drivers say they wait at least 3 hours at docks – lost time that reduces handling performance and customer satisfaction. Demurrage charges and contractual penalties threaten in the event of delays.

- Traceability & documentation: Every incoming and outgoing weight, every movement of goods must be seamlessly recorded. Traceability is essential, for example to know which truck transported which load at what time – relevant for customs, billing and quality assurance.

- Security & access control: Port areas require strict access solutions. Only authorized vehicles are allowed in; overloading must be avoided (road and rail infrastructure must be protected). Automatic barriers and license plate recognition prevent unauthorized access and increase operational safety.

- Automation & sustainability: In the face of growing cost pressure and sustainability targets, ports are turning to digitalization. Networked systems reduce paperwork and human intervention. This reduces idle times (less exhaust fumes from running engines) and improves space utilization, which makes ecological sense. Modern technologies such as 5G enable real-time data – a digital twin of the port can map every movement live in order to optimize processes.

These challenges show: Intelligent yard management and automation are essential. A digital yard logistics system enables shorter waiting times, higher handling capacity, fewer errors and more safety in daily port operations.

The truck scale as the gateway to digital yard logistics

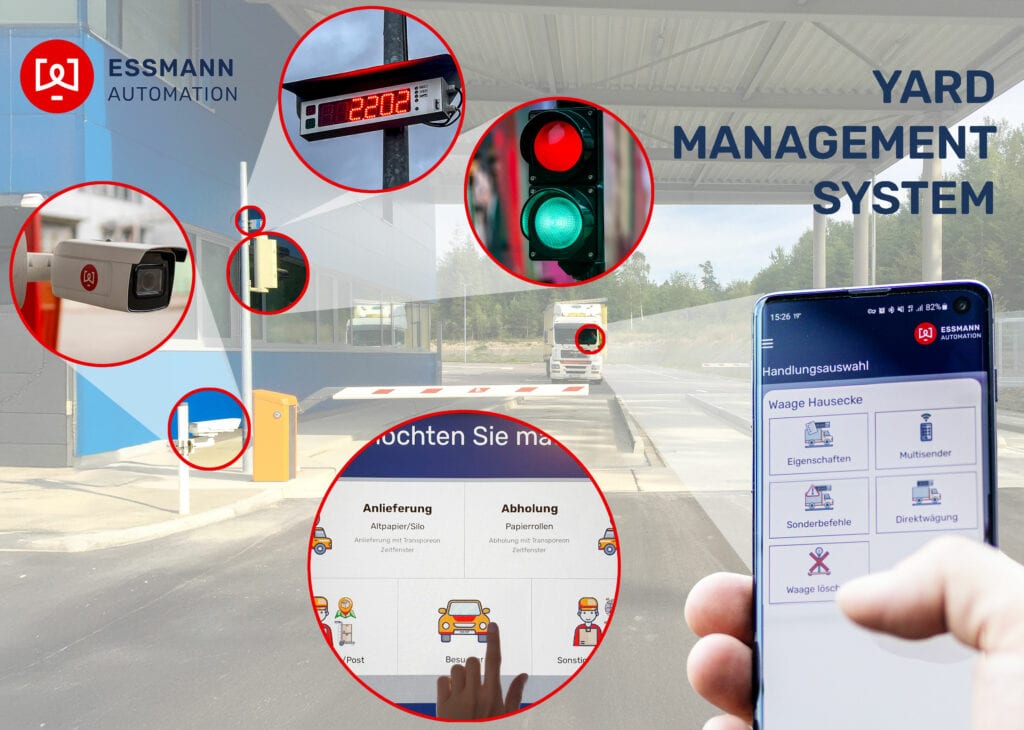

Every yard logistics system usually starts with a truck scale – it is the “gateway” to a digital yard management system. Why? Because this is where all the threads come together: At the scales, an incoming vehicle is identified, weighed and recorded in the system. Modern truck scale solutions from ESSMANN turn this process into an automated check-in process:

- First and second weighing: The tare weight of the truck is recorded on entry, and vice versa for the gross weight on exit. The software automatically calculates the net quantity transported from both. This double step – inbound and outbound weighing – forms the basis for seamless quantity recording in Yard Management.

- Automatic identification: the driver and vehicle are recognized at the scales License plate recognition (ANPR) automatically detects the license plate. Corresponding weighing terminals and touch panels can provide multilingual driver guidance or read the vehicle ID via RFID, for example. All this is done without the driver having to fill out long forms.

- Real-time access control: The scales are typically linked to barriers or roller shutters. If a truck is authorized to enter and has been weighed correctly, the gate opens automatically. Similarly, when a truck leaves, it is ensured that all data is recorded before the barrier opens. There are no system discontinuities: the scales, sensors and gate control system are seamlessly interlinked. The implementation of safety checks and the connection of test databases in accordance with ISPS are naturally part of our standard.

- Data hub: All information recorded at the scales – weights, time stamps, vehicle data and, if required, scanned load documentation – flows directly into the yard management system and ERP. This creates a digital twin of the yard: dispatchers can see live which vehicles are on the site, what load they have and where they need to go. On this basis, routes on the site can be optimized (route control), loading yards can be better coordinated and loads can be checked for correctness.

In short: the weighbridge acts as a smart gate. It makes the yard “permeable” for data, not just for vehicles. If this entry process is digitized, the door to complete yard automation is open.

Comprehensive ESSMANN solutions for port yard management

ESSMANN offers port operators intelligent complete solutions from a single source – from robust weighbridge to the fully networked yard control. The special feature: All components come from the same manufacturer, are optimally coordinated and avoid media discontinuities. Our software is perfectly coordinated with our hardware. So you get everything from a single source: weighing expertise from the load cell to the connection to your ERP system. This comprehensive portfolio covers many requirements in port areas:

- HE-SFK underfloor truck scales: The underfloor truck scales are space-saving (flush with the road surface) and extremely resilient – ideal for busy port entrances. It is supplied as a complete system with prefabricated foundations, can be driven on lengthways and crossways and is designed for continuous operation. With load-bearing capacities of up to 60 t (200 % overload reserve) and optional WHG or ATEX design, it can withstand port conditions such as heavy goods traffic or hazardous goods. The following can be integrated traffic lights, barriers and license plate recognition directly on the scales. The HE-SFK serves as a reliable gatekeeper for yard management through first and second weighing at the entrance and exit.

- EWP Suite weighing software: The digital heart of the solution. The ESSMANN EWP Suite is a modular multi-user weighing software that networks all weighing devices and peripherals. For example, it enables the management of several scales (road, rail, crane) at the same time and connects seamlessly to the ERP or merchandise management system. This creates a continuous process chain from the scales to invoicing – without manual data transfer. In ports or industrial parks, EWP Suite can bundle weighing bridges, silo scales and loading systems in a single platform. Thanks to the modular structure, exactly the functions required by the operation are activated – whether for a simple weighing station or a complex KRITIS environment. Updateable and with German IT support directly from our company, EWP Suite provides investment security in the long term.

- Bulk goods, container and big bag scales: Ports not only handle containers, but often also bulk goods such as grain, ore, coal or chemicals. ESSMANN offers special scales for this purpose: Container scales (e.g. for silos or tanks), belt and dosing scales for continuous conveying flows as well as big bag filling scales for filling large bags. These solutions allow precise weighing directly in the material flow – for example when filling a silo or packing a big bag. By connecting to the EWP software, even such weighed quantities can be immediately recorded in the system. In the port, this means that whether bulk goods are being loaded at the quay or packaged – every quantity is recorded exactly and assigned to the correct order, which increases transparency.

- Crane scales for loading processes: Cranes are used in many port handling operations – for example when loading steel coils, project cargo or container movements away from container gantry cranes. Crane scales make it possible to weigh loads precisely during the lifting process. They are integrated into the crane hook suspension or lifting beam and supply weight data to the scales software in real time. The advantage: there is no need for a separate weighing process on the ground and overloads can be detected immediately. For example, a gantry crane with crane scales can ensure that each bag has the correct weight when loading big bags, or a mobile crane can check the tonnage to be lifted beforehand (important for crane stability!). ESSMANN crane scales are robust and suitable for industrial environments – ideal for making loading processes faster and safer.

- Rail scales (static & dynamic): Many port areas are connected to the rail network, for example to transport bulk goods by train. This is where ESSMANN rail scales come into play. Static rail scales (e.g. type HE-GSW) weigh stationary wagons or entire trains precisely, often combined with a truck scale in one system. Dynamic track scales (e.g. HE-DRS or HE-Point) are even more efficient: They record the weight of wagons as they slowly pass over the scales. A train can be pulled over the scales embedded in the track at a constant speed (typically up to ~10 km/h) and each wagon is weighed automatically. The ESSMANN software automatically determines the individual and total weight from the axle data of the wagons. For example, incoming freight trains in the port can be weighed directly as they roll through and checked for overloading – without stopping, so as not to disrupt operations. Loaded tank wagons can also be reliably checked in this way. Yard Management thus also fully integrates rail logistics into the digital process.

- ESSMANN Yard Management System: The yard management system from ESSMANN forms the big picture, in which all the above components work together. It includes modules such as Roller shutter control, section control and license plate recognitionto control all processes from check-in to loading centrally. Examples: Route control guides vehicles through the port area in a targeted manner – whether to the correct loading ramp or to the parking lot. Traffic lights and barriers are controlled automatically to ensure a smooth flow of traffic. The door control system opens warehouse roller shutters or barriers precisely when a vehicle with authorization nahtessmann.com. And license plate recognition ensures that the truck’s master data is called up and processes are prepared in advance as soon as it arrives. All the data collected – from vehicle weights to time stamps and driver information – converge in the yard management system and can be evaluated there. Reports and interfaces allow easy transfer to transport management, warehousing or billing systems. The result: optimized processes and transparent workflows, tailor-made for every port operation.

Everything from a single source: Probably the biggest advantage of the ESSMANN portfolio is its end-to-end solution expertise. From the hardware (scales, sensors, terminals) to the software and automation, everything comes from the same supplier. For the port operator, this means no system discontinuities, simplified interfaces and maximum reliability. Components do not have to be painstakingly integrated from different manufacturers, but interlock seamlessly. Maintenance and support are simpler – after all, one partner knows the entire system inside out. Future extensions (such as additional scales or new software modules) can also be easily integrated without jeopardizing the investment. In short: ESSMANN supplies a complete turnkey system that immediately creates added value and can grow with your business.

Future trends: Why act now?

The port world is changing. Digitalization, AI and networking are being used to increase the efficiency of ports. Projects such as the one funded by the Federal Ministry of Transport AKIDU in Hamburg, funded by the Federal Ministry of Transport, show where the journey is heading: here, trucks are weighed on ESSMANN scales and simultaneously measured using 3D scanners in order to improve the loading optimization of RoRo ships using AI – the aim is to significantly increase terminal handling capacity. Developments in Lübeck with 5G, autonomous scanners and digital twins also underline this: Real-time data and automated processes are the key to competitiveness.

At the same time, the pressure to operate more sustainably is growing. Optimized yard logistics means less idling and downtime – and therefore lower emissions and energy consumption. Efficiency is therefore both an economic and an ecological imperativehamburg-business.com. Those who invest in smart yard management solutions today benefit twice over: in the short term through cost and time savings, and in the long term through sustainability and environmental benefits. Many companies achieve a return on investment from such systems after a short time, often within one to two years, as the increased throughput and error reduction quickly pay for themselves.

In short: in the port yard management of the future, scales, software and automation interlock like cogwheels. ESSMANN offers the intelligent complete solutions that port operators and industrial companies need to master the “swell” on the ramp. With a single, integrated solution from the entry scale to the ERP, yards remain transparent, safe and efficient – and your team retains control of tons of cargo in motion at all times.

Request advice from our scale construction experts – discover how ESSMANN can take your yard management in the port to a new level.

Sources and further links:

Port Technology – Five problems with truck congestion at ports and how to solve them

porttechnology.org

Hamburg Business – Port of Lübeck: More overview through digitalization

Hamburg News

AKIDU – Hamburg’s Unikai Terminal digitalizes the receiving and storage of goods

akquinet.com

Federal Statistical Office – Maritime transport 2024: goods throughput 2.3% higher than in the previous year

Federal Statistical Office

Statista – Statistics on transportation and logistics

en.statista.com

DVZ – Drivers’ time is wasted

Deutsche Verkehrszeitung