Remote maintenance of our scales systems via Team Viewer is particularly convenient during the pandemic. It enables us to quickly assist our customers with problems. But nothing can replace personal contact with the people who work directly on the scales. Insights into an on-site appointment at the truck scales in the seaport of Stralsund.

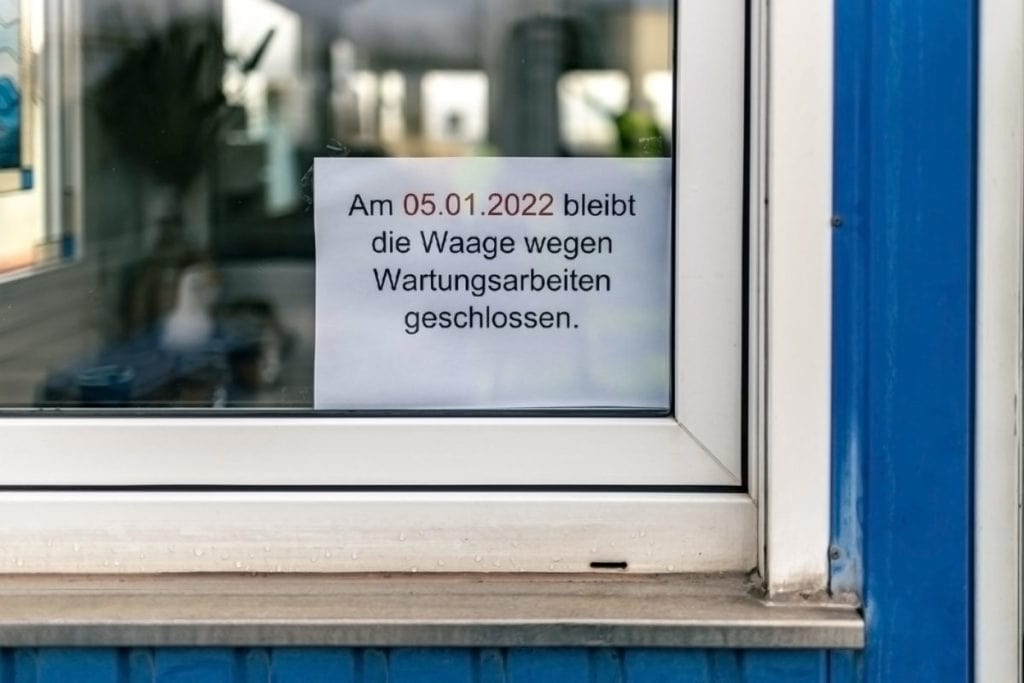

The wind is whistling around the small container in the southern port of Stralsund when our Systems Engineer Sharam Gödel arrives in the morning. Weigher Daniela welcomes him with a coffee. She posted a notice in the window for the truck drivers before Christmas informing them that the truck scales south of the Rügen Bridge are out of service for maintenance today.

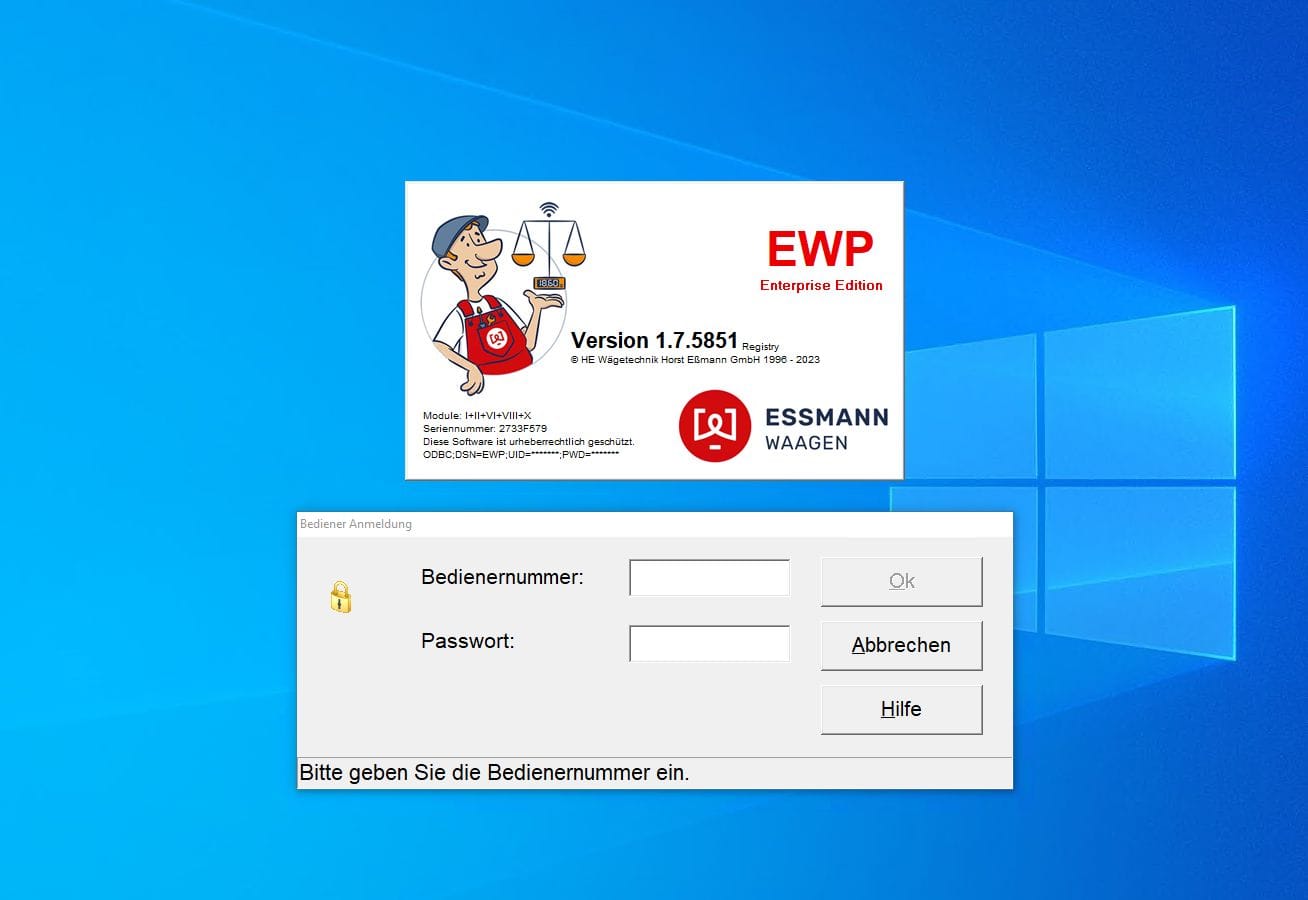

Today, our EWP Essmann weighing program is being converted to a new SQL database and routine updates are due. A task that could theoretically also be carried out remotely. However, it is important for our employees to experience what the processes at a specific location look like from time to time. By talking to the weighers, they find out how they cope.

Repair to the weighbridge in a snowstorm

The HE-ÜWS 18 truck scales with a weighing range of 0.4 to 60 tons were installed in Stralsund’s southern port between the bulk goods stockpiles and the scrap yard in 1994. In addition to building materials, paving stones and scrap, fertilizer, grain and oilseeds are weighed here. Around 180,000 tons every year.

In addition to the usual maintenance intervals, regular updates to our software, the integration of new functions and devices and, of course, regular calibrations, this scale rarely sees one of our technicians. But if necessary, as was the case in March 2018, we even go out in a snowstorm to help. The frosty temperatures of up to -20 degrees Celsius had taken their toll on an almost 25-year-old load cell that had reliably held out up to this point. Now it had to be replaced.

Optimize processes through adjustments

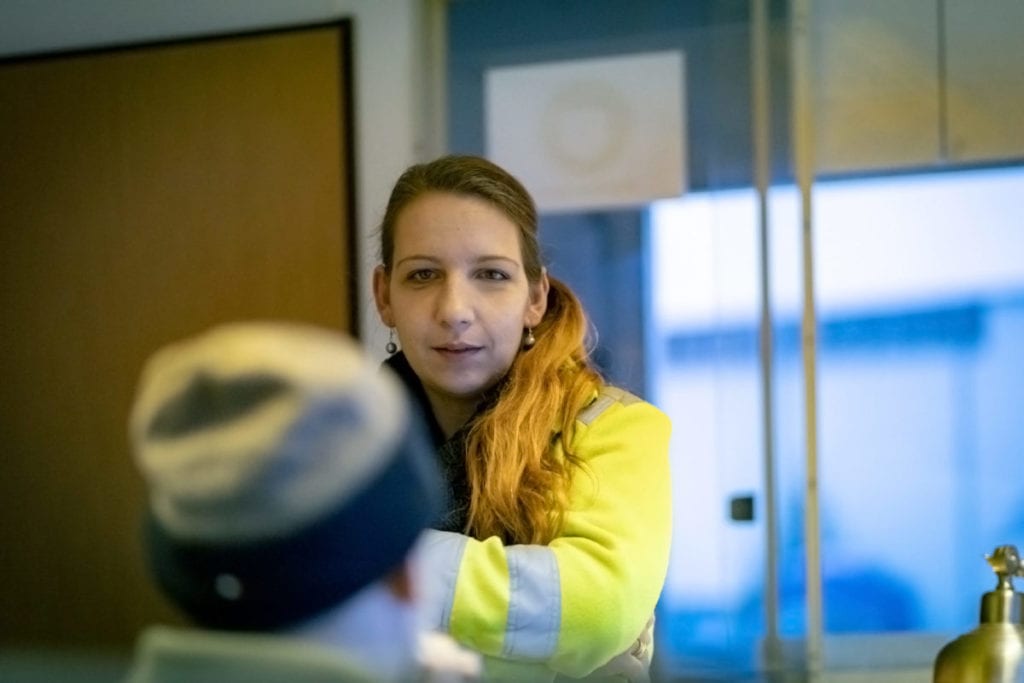

While Sharam Gödel runs the updates, he talks to Dani, the weigher, about everyday processes. Over coffee, she talks about the days when ships are unloaded and 20 or 30 additional trucks queue up at the truck scales. Then things have to move quickly, because the regular customers from the day-to-day business also want to be processed quickly on such days.

Dani explains that a different sorting in the yard list could help to find the trucks for the second weighings more quickly. Also, some of the information in the search result of the yard list is not relevant for the weighers in this situation and is more of a nuisance. And the fact that a line is quickly slipped in a hurry, a wrong truck is selected for the second weighing and the entire process then has to be canceled sometimes stops operations.

Sharam Gödel nods, sips his coffee and turns to the monitor. The updates are done, now he can devote himself to the individual customization requests that will make life a little easier for the weighers. Meanwhile, Dani climbs onto the wheel loader and tidies up the adjacent gravel heap.

Satisfied hunters are good hunters

At the end of the day, the Essmann weighing program EWP is running with a modernized database, new updates for digitalized operating procedures and some small but effective modifications that make the processes in the southern port of Stralsund easier for the weighers.

Do you need an update, upgrade or customization for your scale? You can contact our ESSMANN | Scales & Automation support team by email at IT-Support@essmann.com. In urgent cases, please call +49 40 84000426.

Related products

ESSMANN HE-ÜWS above-ground truck scales in use

Learn more