Robust, precise and dynamic Rail scales with more modular Software – developed for the Liquid gas–Weighing in the Wagon traffic

ESSMANN | Waagen & Automation has developed the ➚Evonik Industries AG has modernized the rail logistics at the Marl site. Two dynamic rail scales of the type ➚HE-DRS 3Mcombined with the ➚weighing software EWP-GWreplace the previous static scales. The foundationless flat scales system enables efficient weighing of a wide variety of train sets.

Marl Chemical Park

Evonik as a customer

The Marl Chemical Park is one of the largest chemical sites in Germany and also Evonik’s largest production site. The site covers an area of more than six square kilometers and provides around 10,000 jobs.

The Marl Chemical Park is one of the largest chemical sites in Germany and is Evonik’s most important production site. Around 10,000 people work on an area of over six square kilometers. In addition to Evonik and its subsidiaries, 17 other companies are based here. The approximately 100 production facilities are closely networked with each other and run around the clock for the most part. Over four million tons of products leave the site every year – often by rail. Energy requirements are covered by environmentally friendly combined heat and power generation, operated by two gas-fired power plants and a coal-fired power plant.

The focus of production at the Marl Chemical Park is the conversion of petrochemical raw materials such as benzene, ethylene, propylene, methanol and phenol into basic, fine and specialty chemicals – from C4 cut to downstream products, from chlorine electrolysis to PVC, from acetylene to tetrahydrofuran, from fatty alcohols and ethylene oxide to surfactants and from acrylic acid to butyl acrylate.

We find all of these products in areas of everyday life. Whether wallpaper or paint, shampoo or hygiene products, latex mattresses or pharmaceuticals, components for car manufacturing and fuel additives as well as insulating materials for the construction industry – the product range is diverse. Even yoghurt and margarine cannot do without these powerful chemicals, nor can many sports articles.

Requirements for wagon weighing

Evonik Industries AG purchased a dynamic rail scale from a competitor many years ago in order to realize the increasing delivery traffic of liquid gas via the track. However, the company was not satisfied with this weighing technology and the scales were eventually decommissioned.

Instead, two static track scales were installed. However, these were no longer able to handle the increased volume of traffic and a dynamic solution was sought to further optimize and modernize handling.

ESSMANN had already successfully installed dynamic rail scales at other Evonik sites. The Marl site therefore opted for the proven technology, including software integration into the existing rail transport system.

The two existing static track scales were removed and scrapped for the installation of the dynamic track scales from ESSMANN | Waagen & Automation. The track bed was then prepared for the installation of the new dynamic scales in accordance with ESSMANN | Waagen & Automation’s specifications.

Technical solution

In joint project planning discussions, the appropriate system from ESSMANN | Waagen & Automation was selected on the basis of the wagon fleet, track plan, required accuracy and software.

The HE-DRS 3M rail vehicle scale enables the dynamic weighing of coupled wagons and entire trains as well as the static weighing of individual wagons. A robust stainless steel weighing terminal with color display and alphanumeric keypad controls the system. Weighing and delivery bills can be printed out directly. The scales can also be operated remotely using the EWP-GW software.

The weighbridge is made up of weighing modules, with each module operating as an independent scale. Depending on the wagon to be weighed, the modules are automatically interconnected by the system so that each wagon is weighed as a whole. The scale can therefore also be used for weighing liquid goods in standard tank wagons, as both bogies or axles are weighed simultaneously (no load changes between partial weighings!). Depending on the length of the wagons, one or two modules are used for the weighing process.

The system weighs the wagons fully automatically. The weigher does not need to enter any data about the length and number of axles of the wagons before weighing. The scale is suitable for weighing all standard DB Cargo and VTG wagons (2-, 4-, 6- and 8-axle wagons) as well as for most special vehicles.

The HE-DRS rail vehicle scale for dynamic and static weighing of rail vehicles complies with the applicable DIN standards, the regulations of the Physikalisch-Technische Bundesanstalt (PTB) and the OIML recommendations. ESSMANN | Waagen & Automation has been approved for this purpose by the Physikalisch-Technische Bundesanstalt (PTB).

System details dynamic track scales

The scale is a solid welded steel construction and consists of one or more scale modules arranged one behind the other and bolted together with bridge girders on which the rails are mounted. The bridge girders are supported by load cells on the base frame, which is founded directly on a compacted ballast bed in the track system. No foundations or complex ballast bonding are required, which – compared to other solutions – also reduces the cost of on-site services.

All steel parts are steel blasted, the DIN parts are galvanized, all other parts are painted with a primer and top coat.

The rail superstructure, i.e. the bridge girders, consist of factory-new Vignol rails with a precisely fitting transition to the existing tracks. ESSMANN | Waagen & Automation also supplied the connecting rails, including the required mechanical safety devices and all necessary fastening components.

An EWS is used as a display and input terminal for signal processing. The program sequence is determined by the EWP-GW weighing software for track vehicles installed in the weighing terminal and on the scale PC. The legal-for-trade industrial weighing terminal EWS in a robust stainless steel housing is suitable for harsh industrial or outdoor use. The terminal is designed for demanding weighing tasks and yet is very easy to operate. In addition to the excellent visualization via a colour TFT display, the high processor and measuring speed, the EWS offers completely new possibilities for integration into control systems and/or networks.

Mounting the dynamic track scale

First of all, the track bed or excavation pit must be prepared by a track construction company in accordance with drawings and specifications from ESSMANN | Waagen & Automation. This can be commissioned by the customer or by Essmann. In any case, ESSMANN | Waagen & Automation will accompany and supervise the work to ensure that the scales can measure with the required accuracy at the end.

The three-module track scales are assembled using a crane. The modules are delivered individually on trucks and lifted into the excavation pit by the crane using the crane eyes provided. This solution makes it easy to move the scales to a different location at a later date.

The individual modules are screwed together, aligned and wired after craning.

The control components are installed in a control cabinet housing with a glass door, which also houses the server components for operating the EWP-GW weighing software.

Of course, the scales are also commissioned by service technicians from ESSMANN | Waagen & Automation. The scale modules are interconnected and the dynamic rail scale is fully configured and adjusted.

Calibration of a dynamic track scale

The dynamic rail scales from ESSMANN | Waagen & Automation are calibrated in two stages. First, the scale is calibrated statically. For this purpose, calibrated weights are applied to the rails and the modules and the scale is first adjusted and calibrated like a static track scale. The calibration weights are transported to the location of the track scale by means of a calibration train and not by several trucks with loaded calibration weights. This saves fuel, protects the roads and is better for the environment.

The track scales are then dynamically calibrated. For this purpose, a reference train is weighed on the statically calibrated scales and then dynamically weighed. Depending on the accuracy class, the dynamically determined weights of the individual wagons may then only deviate from the statically determined weight by a certain value.

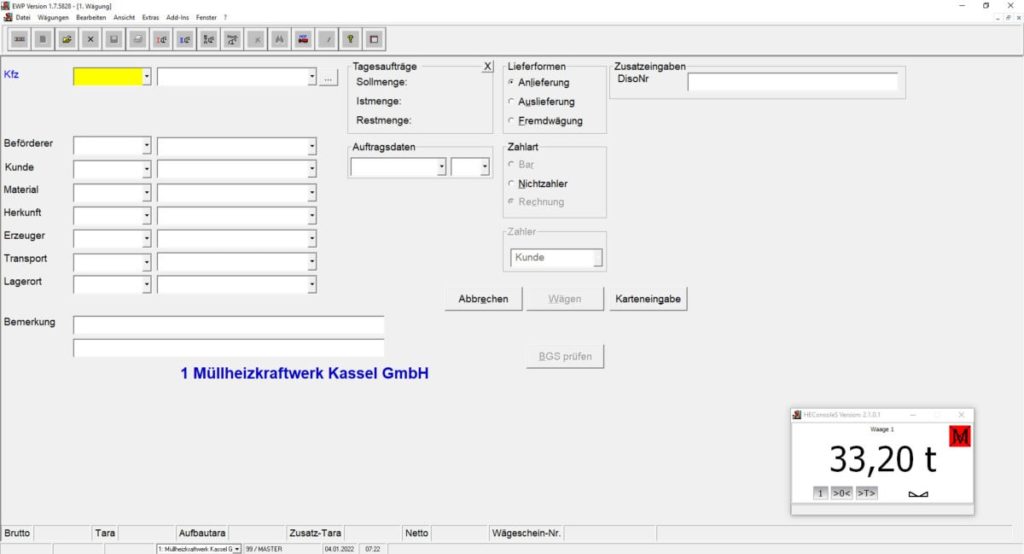

Weighing software

The dynamic track scale is operated via the EWP-GW software package. This makes it easy to record and edit weighing data for any number of clients and plants. With the tools for recording (first and second weighing, gross, tare and net weighing via stored or tare weight), weighing operations can be carried out quickly. First weighings from the train list can be visualized, revised, planned and managed up to the second weighing. The EWP-GW software also contains improved solutions for displaying weighings and creating weighing tickets.

In this case, EWP-GW was equipped with an additional module that enables an interface to the higher-level railroad software. This was implemented in a joint effort between ESSMANN | Waagen & Automation and EVONIK. Wagon data is provided by the EWP-GW software (e.g. wagon sequence with UIC numbers). The weight data is automatically assigned to the corresponding wagons after recording. The weighing result is then transferred back to the higher-level software.

Why ESSMANN?

Many companies offer track scales – but the HE-DRS clearly stands out in terms of design, technology and project integration. Our customers choose ESSMANN because we offer more than the standard:

- True modularity: The HE-DRS is available in 1M, 2M and 3M versions – this means full adaptability to track lengths, wagon types and space conditions.

- Foundationless construction: Our scales do not require expensive concrete foundations. They are installed directly into the compacted gravel bed – an enormous cost advantage in planning and construction.

- Maximum accuracy – even dynamically: The HE-DRS complies with accuracy class OIML R106 up to class 0.2 and works with a digit increment of 0.05 t – calibratable for dynamic AND static weighing.

- Automatic wagon detection: no operator intervention required. The system automatically detects the wagon length, number of axles and direction of travel. A convenient and safe solution, especially for changing train compositions.

- Comprehensive automation: Whether UIC number recognition or direct integration into ERP and control systems – the EWP-GW software offers flexible interfaces and fits perfectly into existing IT structures.

- Sustainability in practice: initial calibration is carried out with a calibration train, not with heavy goods vehicles on the road – this reduces emissions and logistical costs.

- Project expertise included: ESSMANN can take on the entire project planning on request – from coordination with the track construction company and construction supervision to integration into the IT system and commissioning.

These and many other advantages are appreciated not only by operators of large chemical parks such as Evonik, but also by rail logistics companies, port operators and industrial companies with their own sidings.

If you have any questions about the project, the HE-DRS dynamic rail scales or your specific application: Talk to our team! Our scale construction experts will be happy to advise you.