Why producers and distributors need filling scales and fill level checks

Various materials need to be weighed in filling plants, including fuels, liquefied gases, oils, liquids and dry mixtures. Weighing the quantities of materials ordered or sold is an important part of the liquid and bulk goods business.

ESSMANN supports its customers in developing a weighing system for their filling operation. This system streamlines workflows, enables fast and efficient measurements and feeds data into any desired organizational or recording system. Our scales can interface with various technologies and provide all the digital or analog data your filling station needs. We help you to reproduce a recipe with mechanical precision and relieve your production line of unnecessary costs.

Level control as a supplement to the weighing process

Fill level controls are used in semi-automatic and fully automatic filling and loading processes. They are part of the feeding systems, which comprise a feeding device and a control unit. Accuracy is of great importance here.

During the filling process, the material is usually weighed and filled quickly. Some product always remains in the air between the feeder and the base of the container. Dosing is completed even though the product has not yet been fully weighed.

In order to still achieve precise results, the ESSMANN weighing software uses special algorithms and procedures. These enable fast filling and still deliver highly accurate results that meet the legal requirements.

The different types of filling machines and the integration of scales

Choosing the right filling machine requires careful consideration of various aspects. Which filling machines are suitable for your products? Which system meets your company’s volume requirements? Which containers are suitable for filling your products? Is the machine flexible enough to adapt to changing recipes? Does the filling method affect the properties of the liquid? How complex is the maintenance and cleaning of the machine? What level of automation do you require?

The filling scales must also be adapted to the requirements: they should be compatible with different filling methods and be able to be seamlessly integrated into existing systems. They must also comply with the requirements of the EU Prepackaging Directive and the German Prepackaging Ordinance. A high level of accuracy is essential to ensure the correct fill quantity. We would be happy to advise you on integrating scales into existing systems or purchasing new filling systems so that you can find the right solution for your requirements.

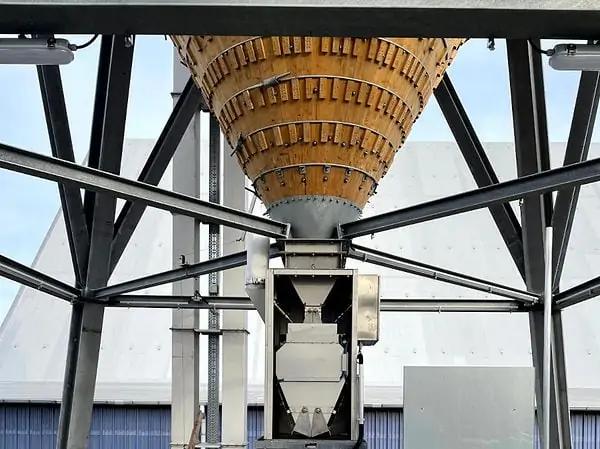

Scale builder tip: Bulk scales

What exactly can bulk scales do? Mixing, blending, dosing, portioning, checking and general weighing of bulk materials, pastes and fluids are just a few examples of processes that require a bulk scales with hopper system. Click here for more information: