What load cells are available and where are they used?

The most commonly used types of load cells are Bending beam and shear beam load cells. Our bending beam force sensors offer a wide range of variants and accessories, making them ideal for use in filling machines, industrial floor scales, hopper and silo scales as well as in areas such as on-board weighing in vehicles, medical devices and process control.

For applications with high accuracy requirements single-point load cells have been developed. They are used in industrial scales, filling systems, onboard weighing systems and various applications in the healthcare sector. Due to the special design of the load cell, an off-center load plays only a very minor role in the measurement result.

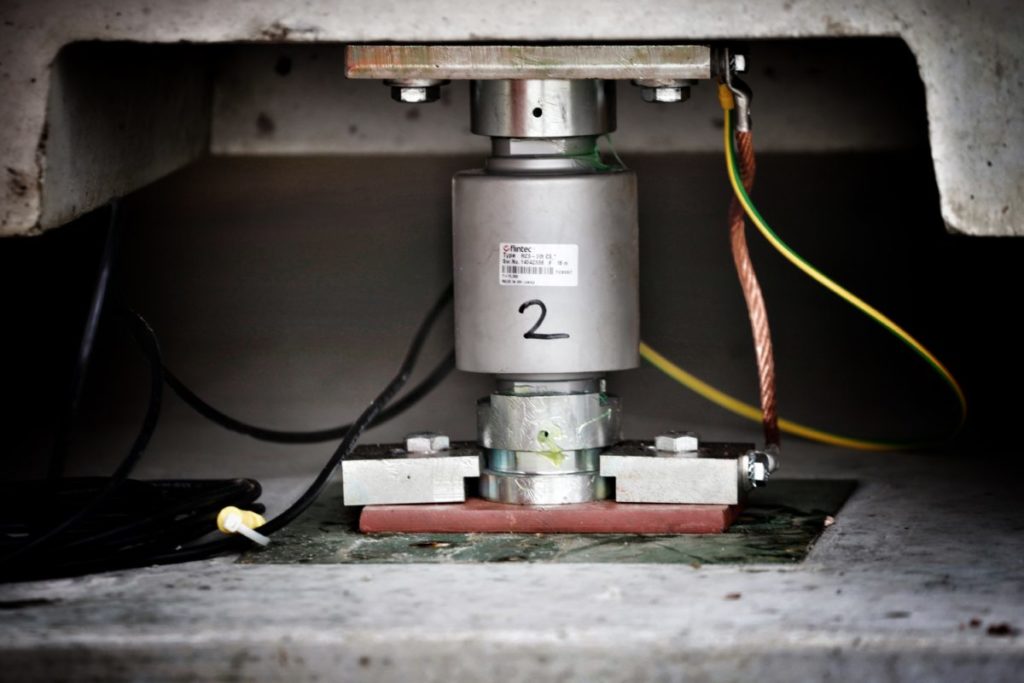

Compression load cells, also known as load cells or DMS pressure sensors, are ideal for use in our high-precision truck scales and rail scales. They are also used in tank and silo scales as well as in high-load industrial scales that require the use of compression load cells.

Planar Beam load cells are specially designed for applications with a flat structure. They are often used in retail scales, medical scales and other devices with limited height. They are usually offered as a set of three or four load cells.

Tension load cells are ideal for various industrial applications due to their robustness and accuracy. They are particularly suitable for weighing tanks and silos, lifting devices and weighing in suspended systems, such as our crane scales.

Partner

Why we like working with our partners

- Quality assurance: Through close, long-term cooperation, we can assess and directly influence the quality of the components and ensure that they meet the high standards required in scale construction.

- Quick troubleshooting: If problems arise, we can communicate directly with the manufacturer to find a quick and efficient solution.

- Customized solutions: This collaboration makes it possible to incorporate specific customer requirements directly into product development. This enables us to offer customized products and solutions.

- Cost efficiency: By purchasing directly from the manufacturers, costs can be minimized and passed on to you as a customer.

These aspects ensure that you as a customer benefit and receive a high-quality, reliable and cost-effective product.

What is a load cell?

A load cell is an electronic sensor that measures the weight of an object. A strain gauge load cell works on the principle of the interaction of force and deformation. When a load is applied to the load cell, it measures the deformation of the material using strain gages. These change the electrical voltage in proportion to the load. To do this, the load cell is supplied with an electrical voltage and the voltage from the load cell is measured and evaluated to determine the weight of the object. Load cells are available in various sizes and designs. The accuracy of a load cell depends on its size and the material of the strain gauges.

Load cells for every application

Load cells are being used in more and more areas of life and work. They can be found in industrial scales as well as in laboratories, hospitals and other institutions. The advantages of load cells are obvious: they are extremely precise and enable exact measurement of weights. In addition, a load cell can be integrated relatively easily into mechanical superstructures. They are an indispensable measuring instrument in many areas of application. They enable a high degree of accuracy when determining weights and are therefore of crucial importance both in laboratories and in production. There are different types of load cells that are suitable for different fields. For example, there are robust models with high weighing ranges for production, but also high-precision laboratory models for research and development.

Laboratory load cells are generally smaller than production load cells and have a lower maximum load. However, they are more accurate and sensitive, making them ideal for weight determination in laboratory scales. Most laboratory load cells use an electromechanical design, which makes it possible to perform very accurate measurements. The unit of laboratory load cells is usually in grams or milligrams. Production load cells, on the other hand, are larger and more robust than their laboratory counterparts and are therefore more suitable for scales in industrial production. However, they are generally less accurate than laboratory load cells. Production load cells are often used in vehicle scales to determine the weight of manufactured goods. The unit of production load cells is usually given in kilograms or tons.

Properties of a load cell

The properties of a load cell are diverse and therefore they can be used in many areas.

The most important features are:

- Accuracy: Load cells are extremely precise. This makes them ideal for applications where high accuracy is required, such as in laboratory analysis or quality control.

- Reliability: Load cells are extremely reliable and can therefore also be used in demanding environments. This is particularly important in production, where heavy mechanical loads often occur.

- Robustness: Load cells are extremely robust and can therefore also be used in harsh environments. This is an advantage, for example, in agriculture or in the extraction of raw materials from mining.

- Flexibility: Load cells can be used for various applications and are therefore extremely flexible.

Scale builder tip: How to choose the right load cell

Before deciding on a load cell with a certain nominal load, make sure that it can withstand the requirements. It is important to include a safety margin to protect the cell from overloads. For example, load peaks can occur when a load is applied dynamically. As a rule, a higher load level should therefore be selected, which is approximately two to three times the measuring range. This takes into account influences such as the maximum load of the scale, the dead load (the dead weight of the body/construction and its uneven distribution), the installation location with dynamic influencing factors such as wind forces in the case of rail scales, agitators in the case of industrial scales or vibrations and shock loads, eccentric loads on the scale and force shunts. Only cells with the same nominal load should be used in a scale. Torsion, bending and transverse loads must be avoided. It is also important whether the scale is to be calibrated. In this case, it must be verifiable and the system consisting of load cells, evaluation unit and cabling must be compatible accordingly.

Thank you for your interest in our load cells. We are confident that you will find the right load cell for your requirements. Our team will be happy to assist you and advise you on choosing the right load cell.