The need to monitor the exact loading of wagons is constantly growing. Overweight and incorrectly loaded wagons not only pose a safety risk, but also cause premature wear on the rail network. This in turn leads to a shortened service life of the track systems and thus increases the maintenance costs of the rail network.

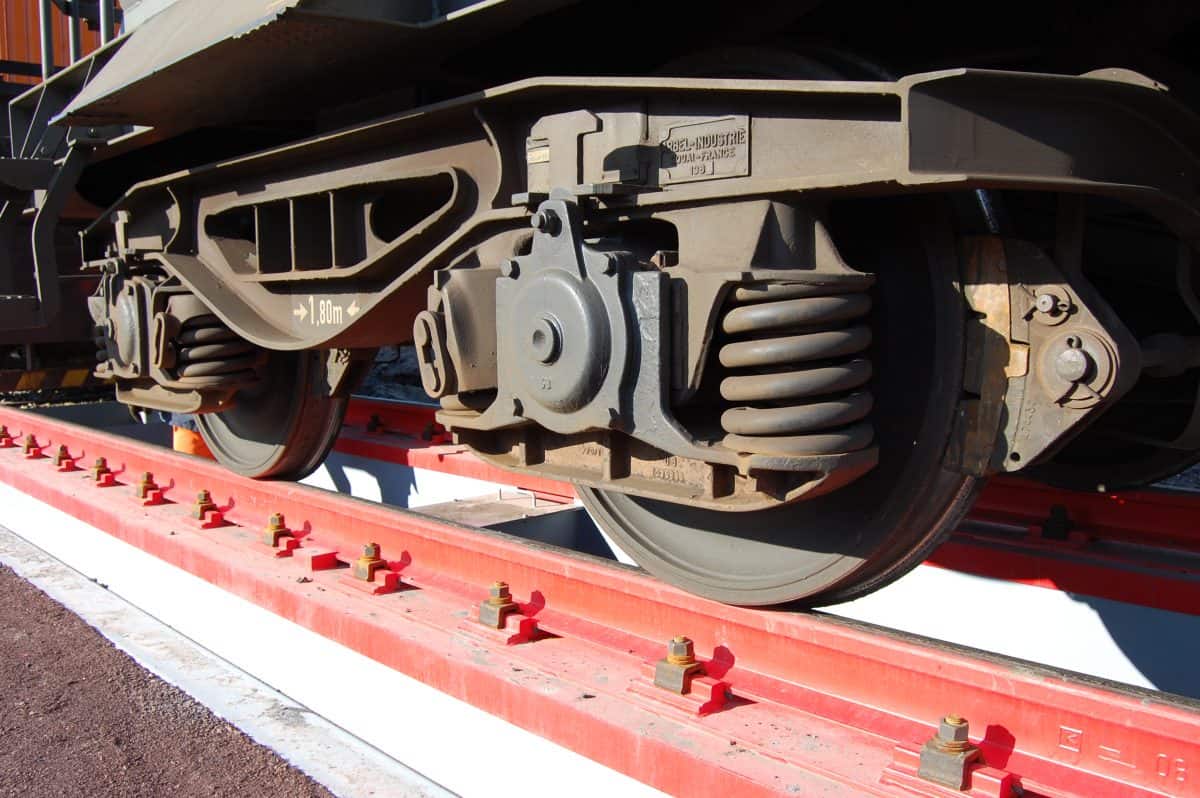

The Point dynamic rail vehicle scale serves as a checkweigher and is one of the most modern solutions on the market for the fully automatic monitoring of wagon weights and loads. The checkweigher can be installed quickly and easily without the need to lay foundations or separate the rail track. The measuring sensors are installed directly in the rail track.

The weighing electronics and the personal computer with the evaluation software are installed either in a protective room next to the track or in a control center, e.g. in the signal box. In both cases, the Point rail vehicle scales function as a fully automatic control system that immediately issues an alarm if an overweight or incorrect load is detected. Locomotive or wagon data does not need to be entered in advance, as the system automatically recognizes the passing trains with the locomotives and their 2-, 4-, 6- or 8-axle wagons.

The system determines the weight of the wheel, the axle, the bogie and the total weight of each locomotive and each wagon. The total weight and the speed of the train sets are also determined. In addition, the system compares the weights between two axles or two bogies to detect uneven loading along the longitudinal axis of the wagons. In addition, the system can be expanded to include side load detection in order to determine uneven loading in the transverse axis of the wagon. All data is clearly visualized on a graphic interface on the PC screen.

The user is able to freely define the alarm limits for wheel, axle, bogie and total weight as well as enter either percentage or weight-related limit values for the longitudinal and lateral deviations of the loads. Alarm messages about overweight or incorrectly loaded wagons appear automatically on the screen and are printed out. They can also be sent automatically as an e-mail to the control room or by SMS to a cell phone, e.g. in the locomotive.

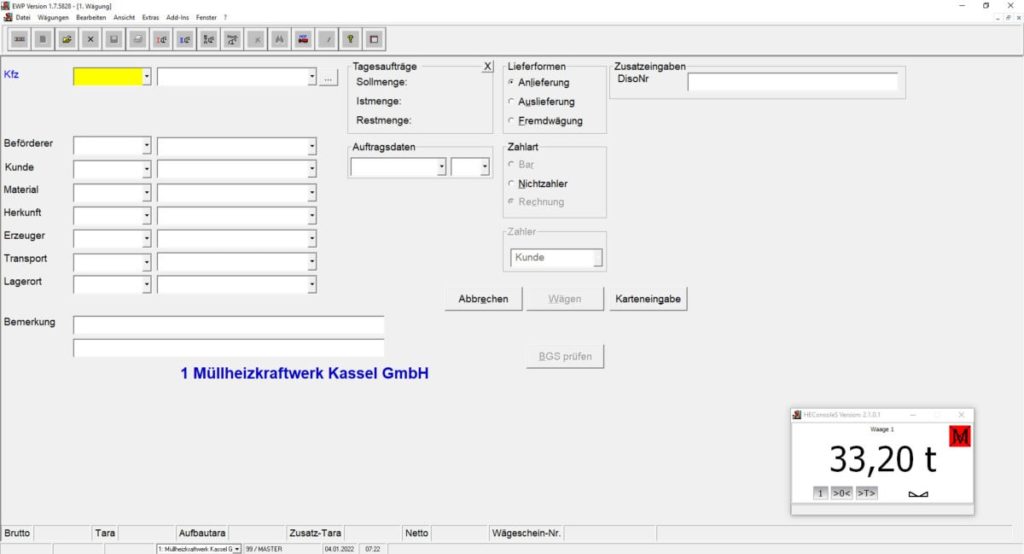

The evaluation program, which runs on a standard PC, is state-of-the-art software. The graphical user interface makes it very easy to use and offers standardized data communication with other programs.

In conjunction with our wagon identification systems WID (transponder technology) or VID (video technology), the system can also be used to monitor wagon movements in relation to customers and products. Information about wagons (customer, product, max. load, empty weight) can be retrieved using the wagon number and displayed on the screen or printer.

Technical data:

| Weighing accuracy: | up to 8 km/h = +/- 0.5 % |

| up to 15 km/h = +/- 1 % | |

| up to 30 km/h = +/- 2 % | |

| Transit speed: | unlimited |

| Weighing range: | 0 – 20 t per wheel |

| Digit step: | 50 kg |

| Interface: | Ethernet (network) |

| Protection class: | Sensors IP 67; electronics IP 55 |

| Operating temperature: | – 40°C … + 50°C |