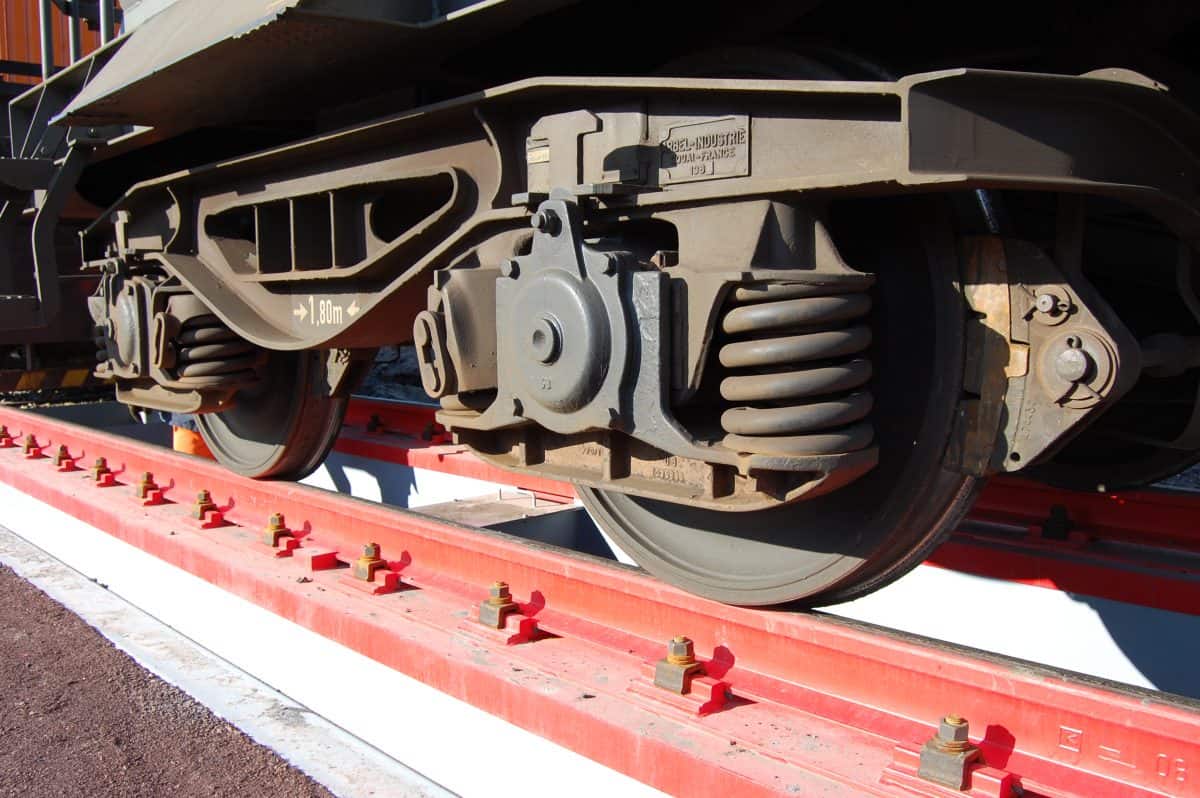

Two modern rail vehicle scales were installed in this project.

These scales have robust foundations and explosion-proof scale bases with load cells.

Their main function is to support the loading process of explosive liquid media.

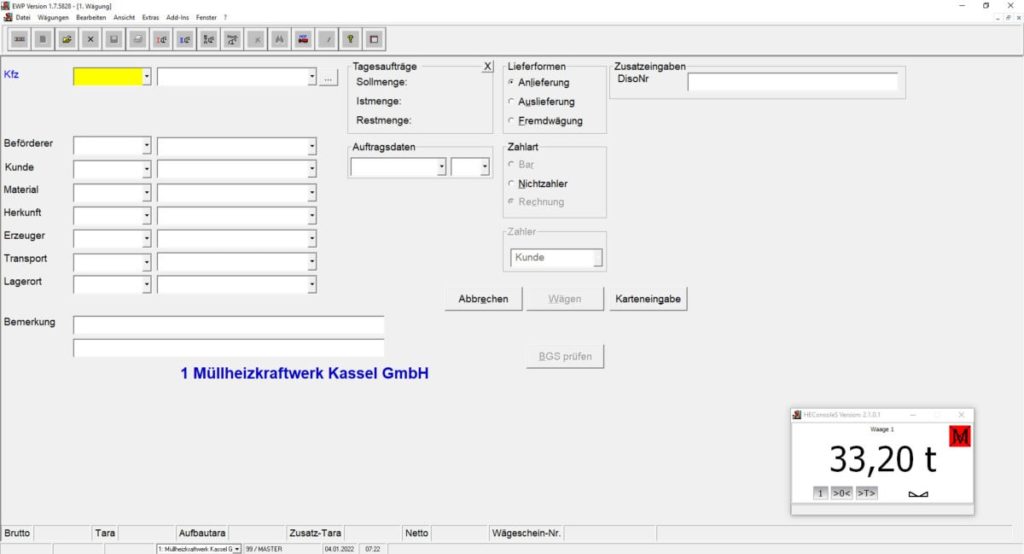

The rail vehicle scales are equipped with system weighing indicators (EWS), which play a key role in this process.

The EWS was connected to a Siemens PC S7 process control system.

This connection was made via a series of inputs, outputs and serial interfaces to ensure seamless communication and data transfer between the systems.

One of the main tasks of the EWS is to control the relevant signals in real time for loading.

This is crucial to ensure accuracy and efficiency when loading explosive liquid media.

In addition, the weights determined by the rail vehicle scales are recorded on external, verifiable data storage devices.

These data storage devices are equipped with removable storage media to enable simple and secure transfer of the weight data.

As a result, all relevant data is stored securely and can be used for future reference and analysis.

In summary, the installation of these rail vehicle scales and their integration with the Siemens PC S7 process control system represents a significant advance in the loading of explosive liquid media.

This project is an example of the use of state-of-the-art technology to improve efficiency and safety in industrial processes.