Hallo und herzlich Willkommen! Ich bin Albert, Waagenbauer, und leider konnte ich noch nicht finden, wonach Sie gesucht haben.

Unser Portfolio

Unsere Automatisierungslösungen

- Wägesoftware

- Lösungen für den Gleisbereich

- Steuerungen für die Schüttgutverladung

- Lösungen für das Yard Management

Kontakt

Unsere letzten Artikel im Waagen-Magazin

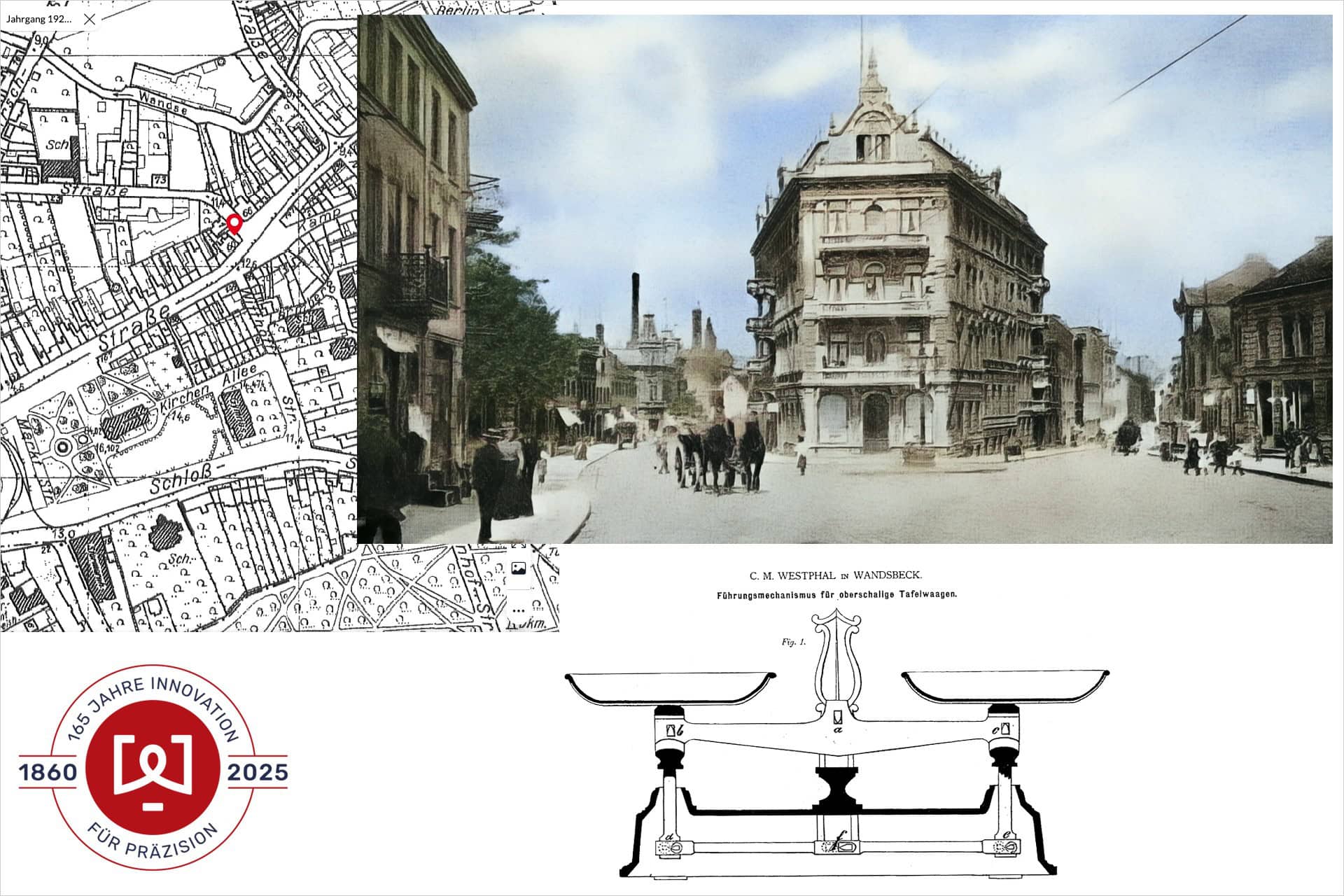

165 Jahre Waagenbau aus Norddeutschland: Happy Founding Day to us!

Es war ein kalter, nebliger Wintermorgen im Dezember des Jahres 1860, als der junge Schlossermeister Christian Moritz Westphal sich von Wandsbek aus auf den Weg nach …

Use Case: Robuste Verwiegung bei Rhenus Logistics mit Fahrzeugwaage HE-SFK 20

Zuverlässigkeit trifft Wirtschaftlichkeit Rhenus Logistics SE & Co. KG zählt zu den international führenden Logistikdienstleistern mit über 1.320 Standorten in über 70 Ländern. Das Unternehmen steht …

Unterflur-Fahrzeugwaagen für VERA: Präzision, wo der Baugrund schwimmt

An der Elbe, dort wo Hamburgs Abwasserwirtschaft ihre Wertstoffe zurückgewinnt, treffen Schwerverkehr und schwierige Geologie aufeinander. In der Verwertungsanlage für Rückstände aus der Abwasserbehandlung (↗VERA) entstehen …

ESSMANN-IT-Support Dennis im Einsatz für das Technische Hilfswerk

Zwei Frachtschiffe kollidieren auf der Ostsee bei Swinemünde. Hunderte Tonnen Rohöl laufen aus, verunreinigen das Wasser und drohen auch den Strand zu verseuchen. Wie gut, wenn …