Hallo und herzlich Willkommen! Ich bin Albert, Waagenbauer, und leider konnte ich noch nicht finden, wonach Sie gesucht haben.

Unser Portfolio

Unsere Automatisierungslösungen

- Wägesoftware

- Lösungen für den Gleisbereich

- Steuerungen für die Schüttgutverladung

- Lösungen für das Yard Management

Kontakt

Unsere letzten Artikel im Waagen-Magazin

Kaufberatung: Wiederlade-Waagen im professionellen Einsatz

In der Werkstatt eines Büchsenmachers, Munitionshändlers, Jägers oder Sportschützen entscheidet die Waage über die exakte Dosierung der Pulverladungen, sei es für Matchmunition, Prüfserien oder individuell abgestimmte …

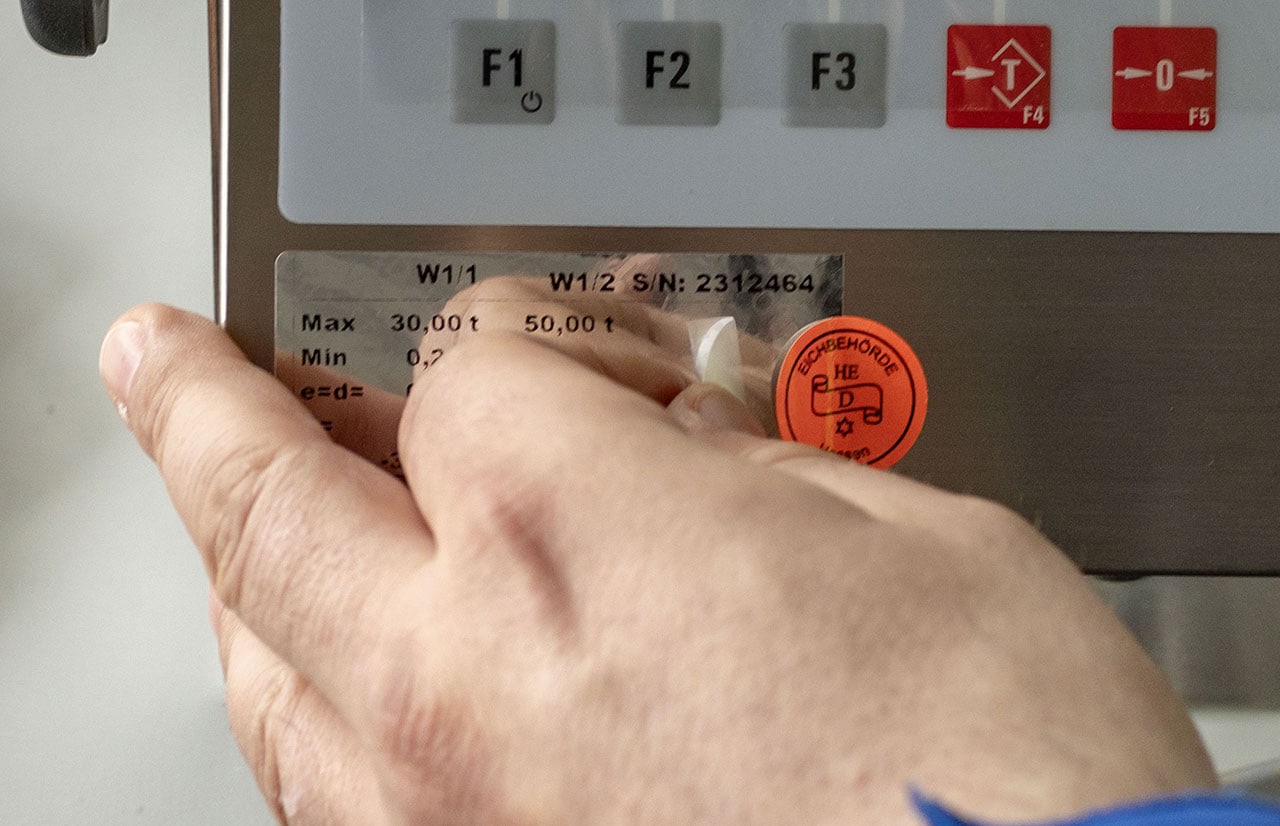

Höhere Eichgebühren seit Januar 2026: Strategien für Waagenbetreiber

Seit dem 01.01.2026 gelten neue Mess- und Eichgebühren. Mit der „Zweiten Verordnung zur Änderung der Mess- und Eichgebührenverordnung (MessEGebV)“ wurden die Sätze bundesweit angepasst. Maßgeblich ist …

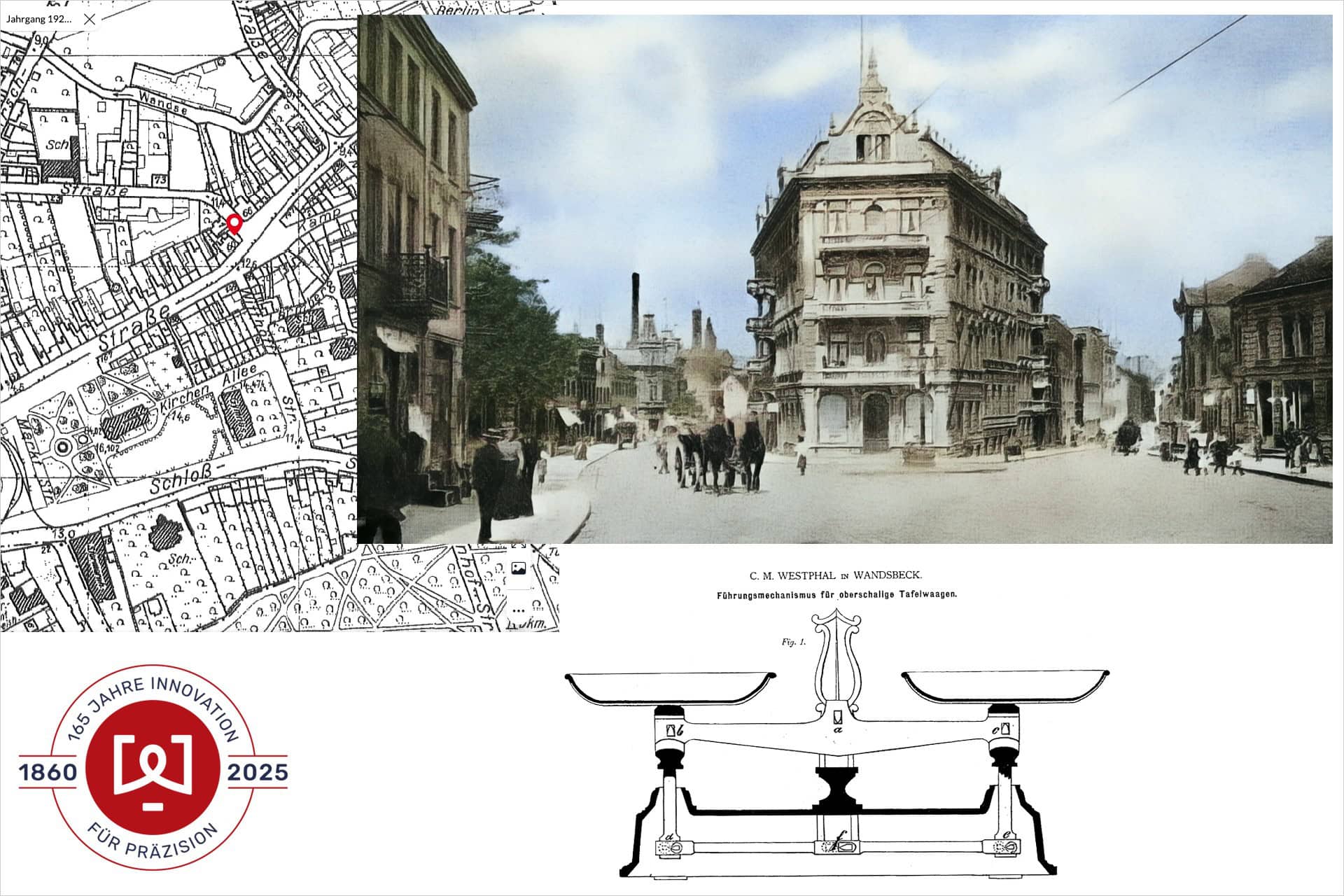

165 Jahre Waagenbau aus Norddeutschland: Happy Founding Day to us!

Es war ein kalter, nebliger Wintermorgen im Dezember des Jahres 1860, als der junge Schlossermeister Christian Moritz Westphal sich von Wandsbek aus auf den Weg nach …

Use Case: Robuste Verwiegung bei Rhenus Logistics mit Fahrzeugwaage HE-SFK 20

Zuverlässigkeit trifft Wirtschaftlichkeit Rhenus Logistics SE & Co. KG zählt zu den international führenden Logistikdienstleistern mit über 1.320 Standorten in über 70 Ländern. Das Unternehmen steht …